Labeling

To generate labeling for your product with a single click, go to your product and click on the "Labeling" list on the left of the screen. By pressing "Formulate", labels are generated automatically using standard BeCPG rules.

You can customize labeling by adding LABELLING RULES to the entity template, or by modifying DECLARATION TYPE.

Allergen labeling

In order for allergens to appear on product labels, they must first be indicated on the raw materials label. Click here for more information.

Allergens subset

If you want allergens with variations (ex: cheese for the milk allergen) to appear in bold, complete the allergens subset in the administration. Click here for more information.

Note: in this case, if the ingredient name corresponds to one of the allergen's subset, it will be bolded and not the allergen itself, which will be placed in brackets next to it.

Modify the formatting

The beCPG standard displays allergens in bold by default. However, you can modify this formatting with a preference rule

Click here for more information.

Manually format the ingredient name

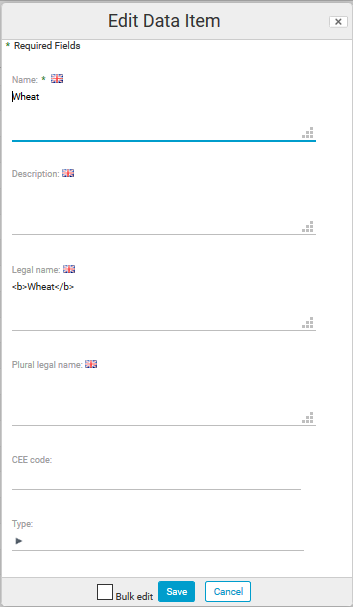

If the bolding of allergens in the labeling as shown above is not appropriate, this can be done by hand directly in the ingredient's legal wording. Translations/languages are independent of each other. You will need to manually modify all ingredient translations.

In the administration, link to the ingredient concerned and edit its properties. In the legal label, add the [html tags] (/utilization/labeling-rules.md#labeling-rulesHTML-tags)you require. Then return to the "Labeling" list and press "Formulate" to see your changes.

Changes made by hand override default changes.

Modification to make eg :the tag at the beginning of the word to put in bold and* at the end

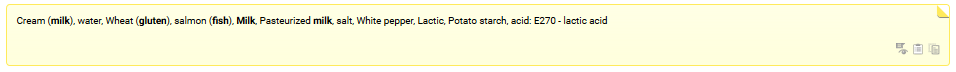

Before modifications:

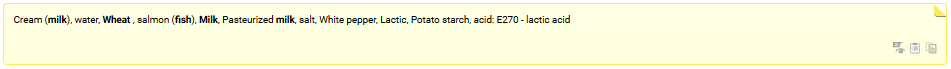

After modifications:

*e.g. In German, wheat allergen = weizen , wheat flour = WeizenMelh The translation WeizenMelh is not recognized by beCPG: WeizenMelh(weizen) However, the allergen subset"wheat flour" does not exist in the standard version, as in most languages the word wheat and flour are dissociated. In this case, it may be useful to manage the allergen manually.

Labeling of Organic product

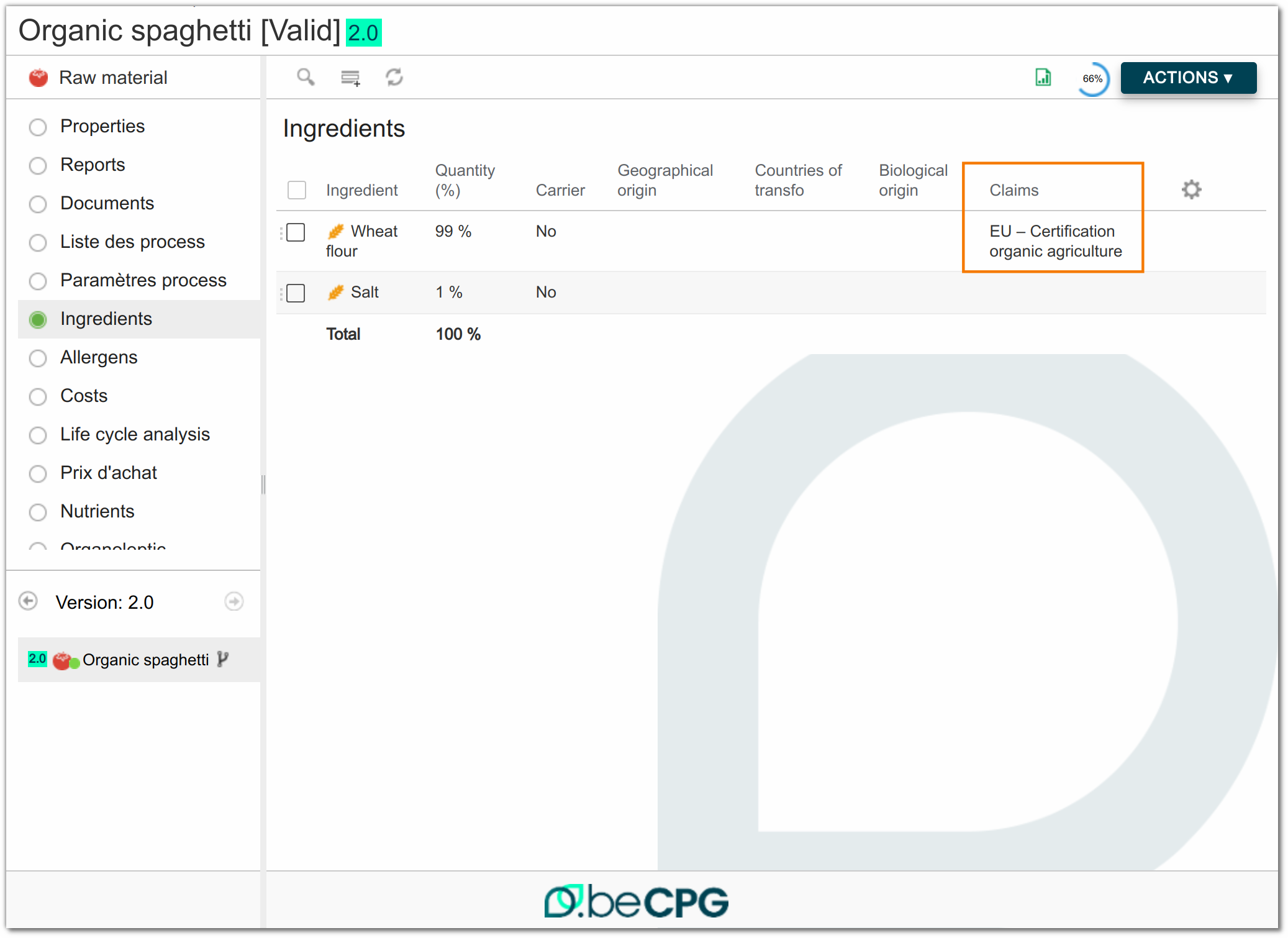

Identifying organic ingredients

In the ingredients list of raw materials, link each ingredient considered as organically grown to the EU - Organic Agriculture claim in the claim field.

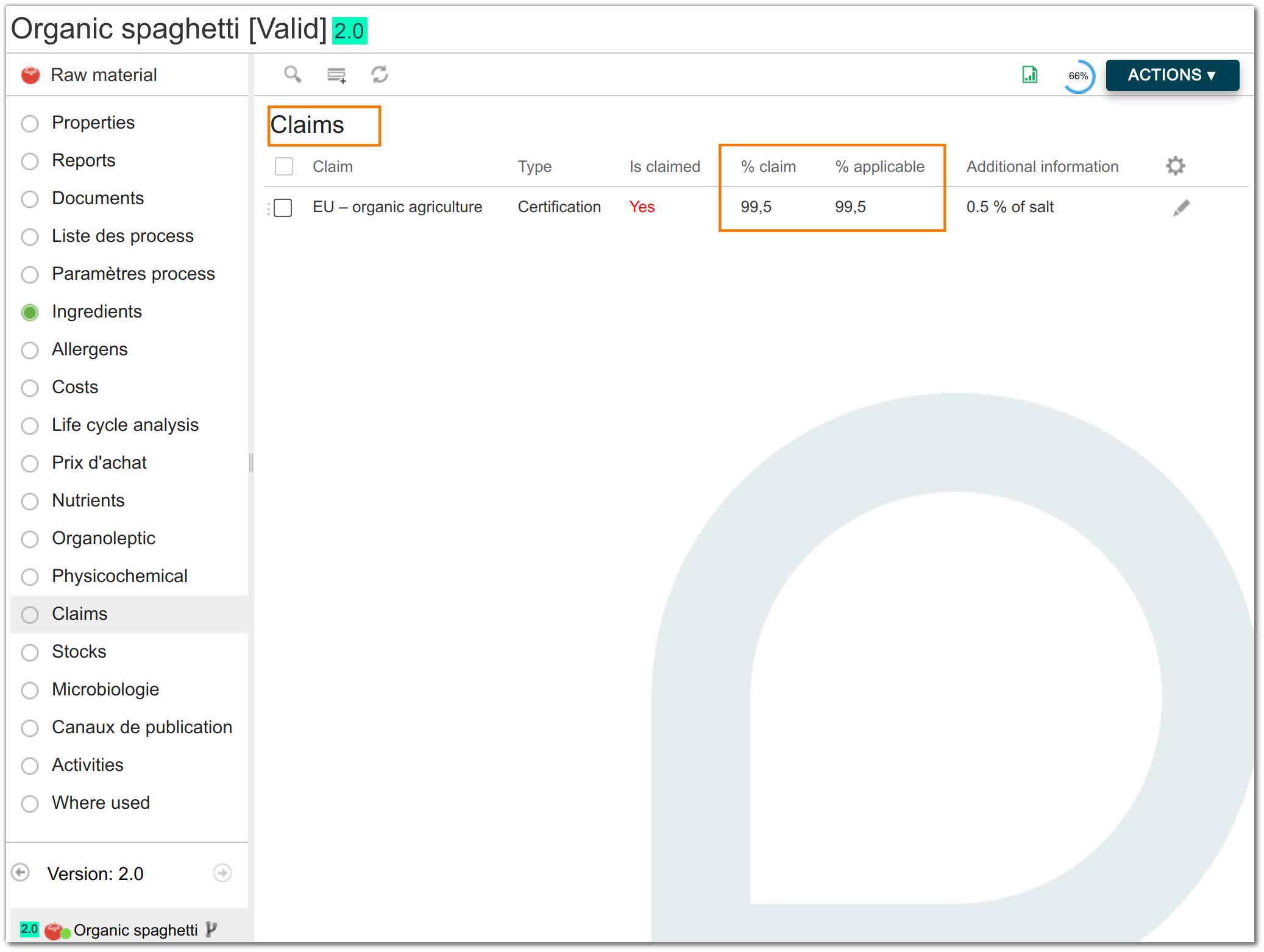

Complete the organic claim

On each raw material, the organic claim must be indicated:

- Add claim EU - Organic Agriculture

- Complete the % claimed and % applicable.

For more information on claims : clic here

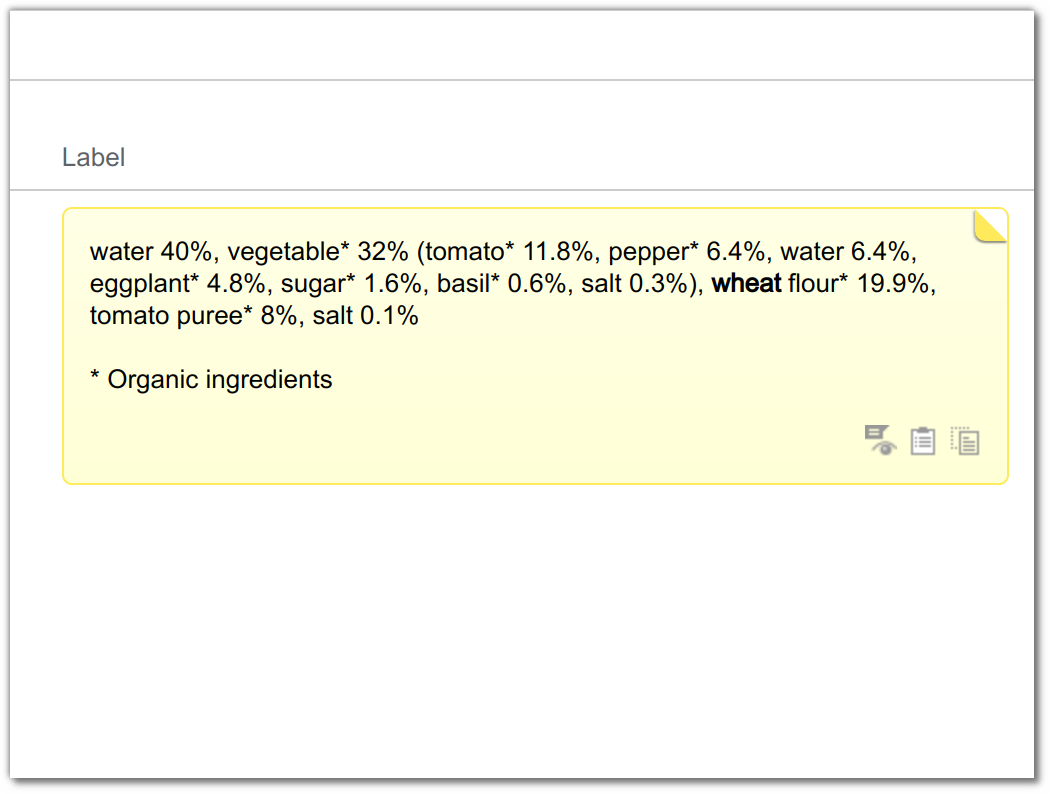

Set labeling rules

On the finished product, in the list of labels :

- Modify the render of your labeling, add the foot note render to the current render.

- Add the labeling rule, footNote

Before 4.2.1 version: For organic ingredients to appear with an asterisk (*) on the product label:

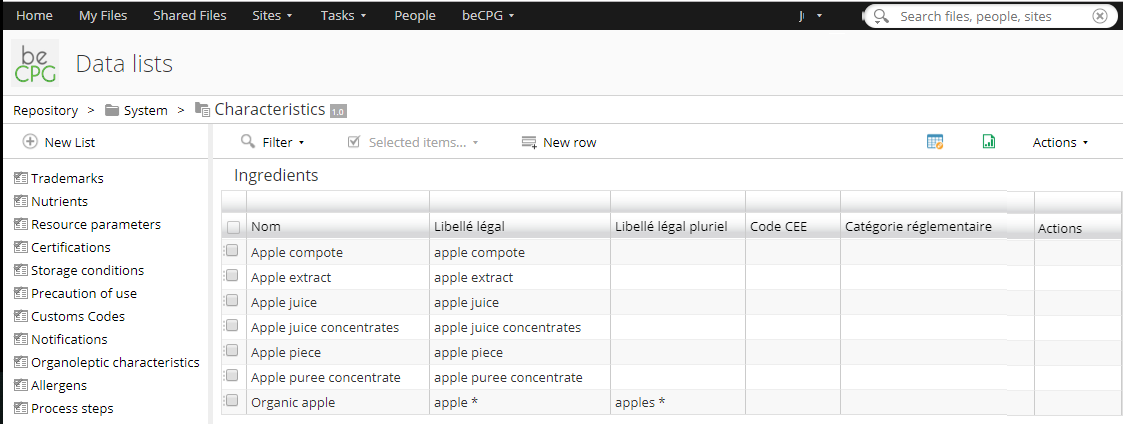

- Create organic ingredients in Administration > Characteristics > Ingredient (e.g. organic wheat flour)

- Add the "asterisk" to the legal name (e.g.: wheat flour*)

These ingredients will only be used for organic raw materials.

Labeling and yield

Labeling with or without yield

It’s possible to integrate or not the yield in the product’s labeling.

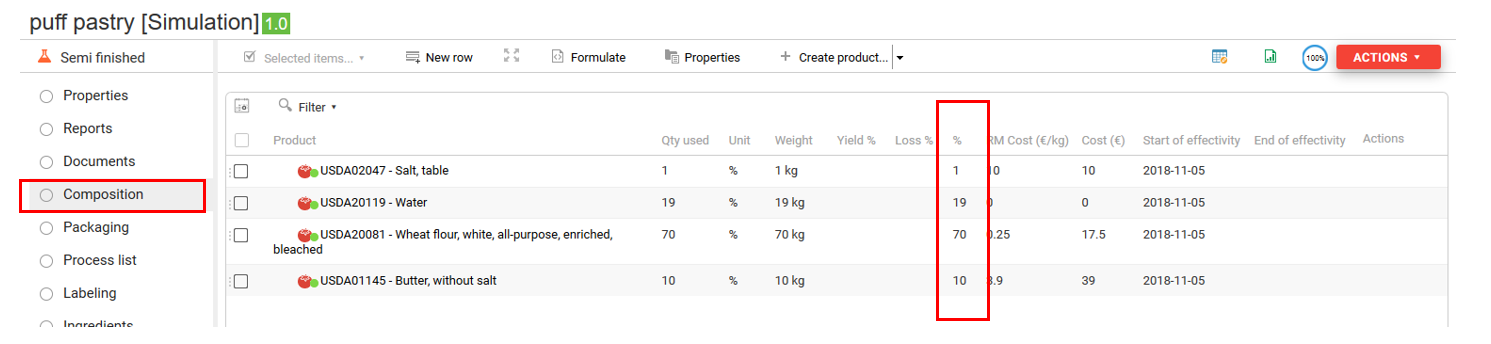

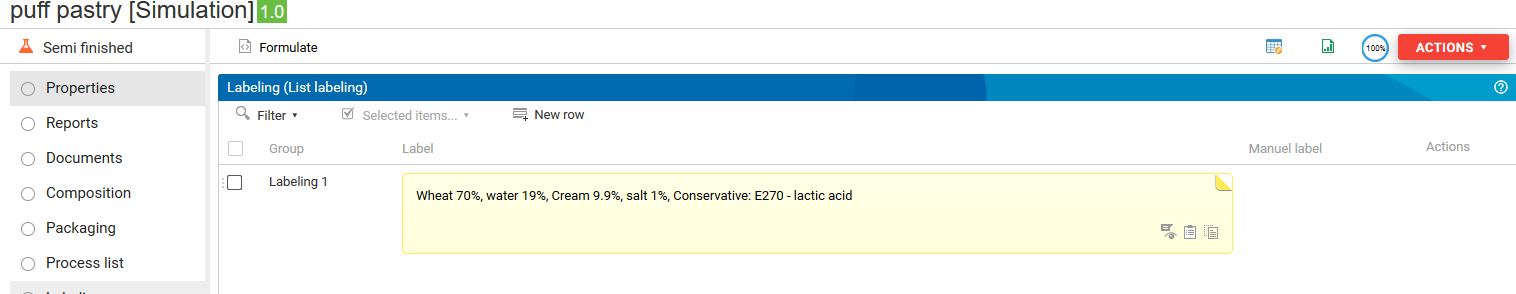

Labeling which doesn’t take into account the yield

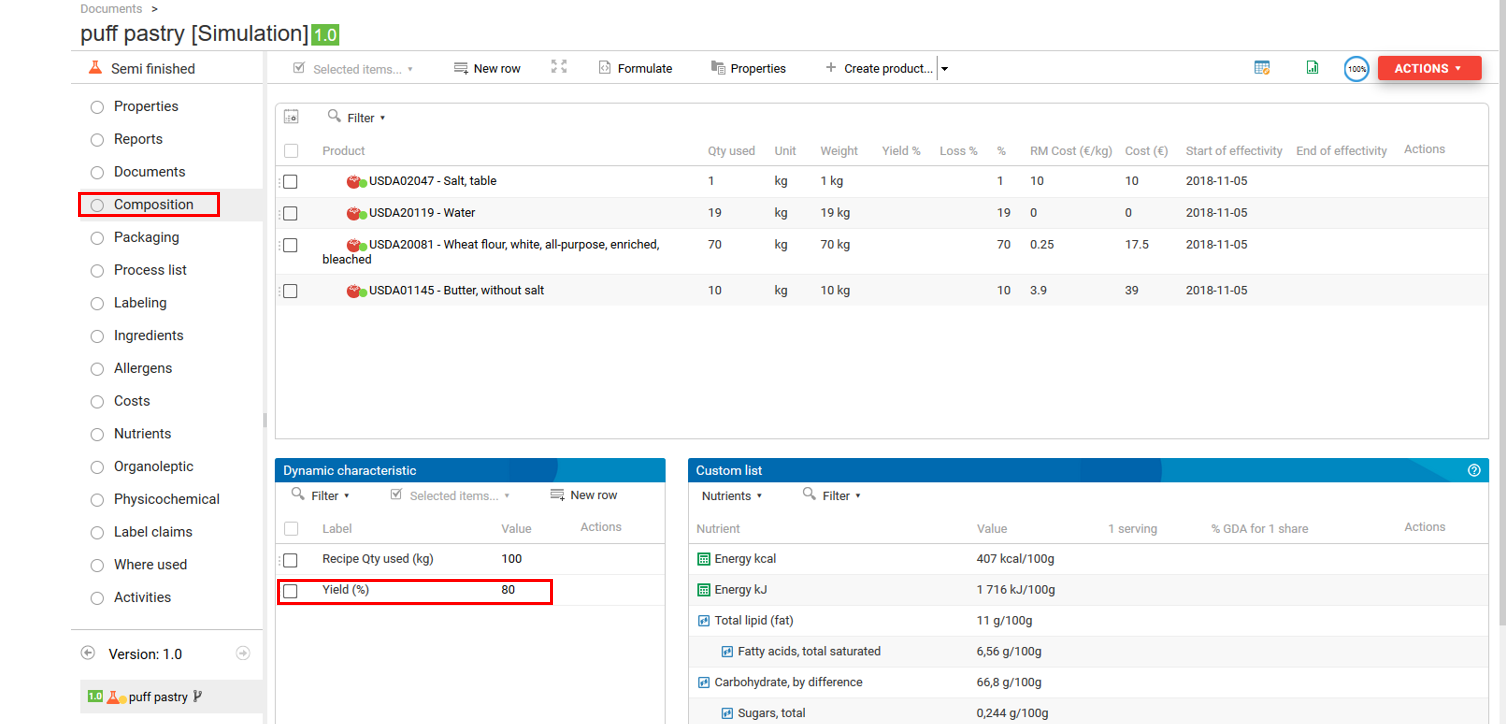

By default, when the formulation is done, the product labeling doesn’t take into account the yield. Thus, the ingredients percentages correspond to the implemented percentages in the raw product.

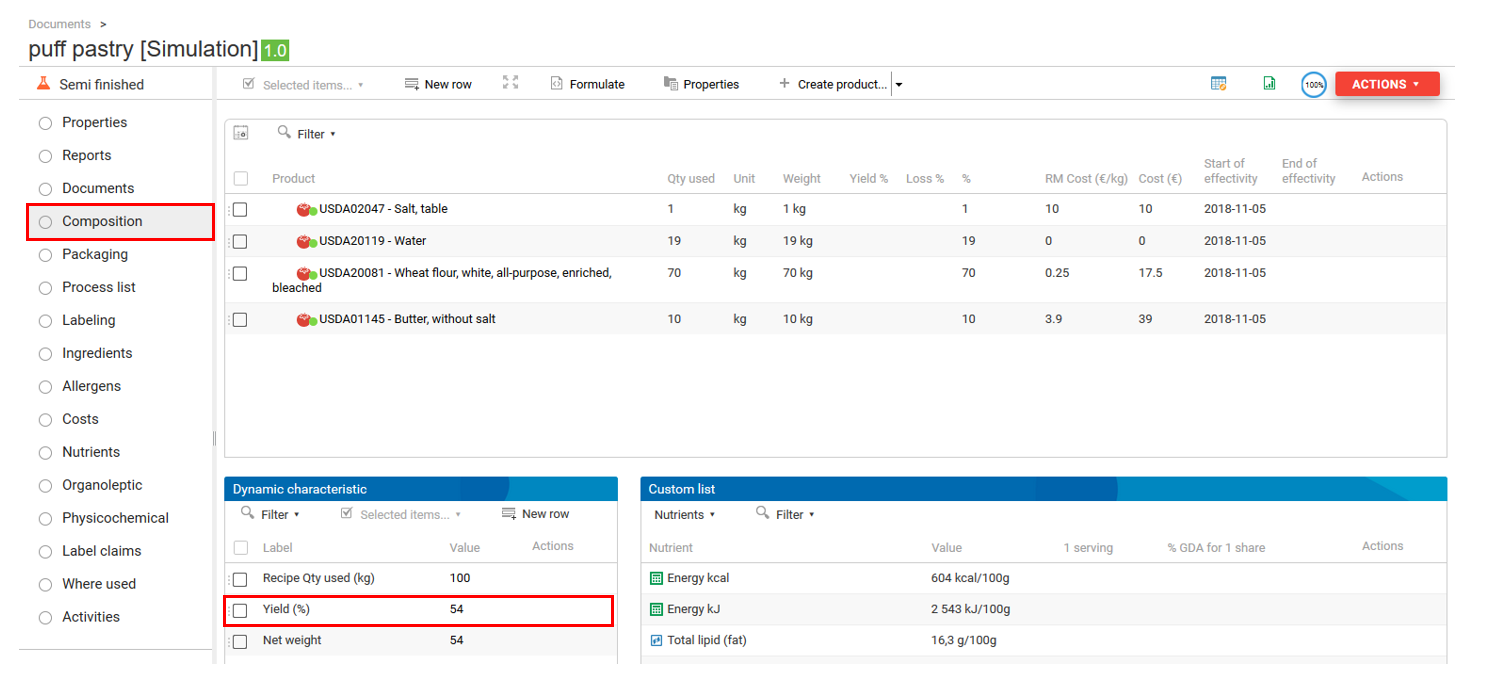

Composition of the raw product:

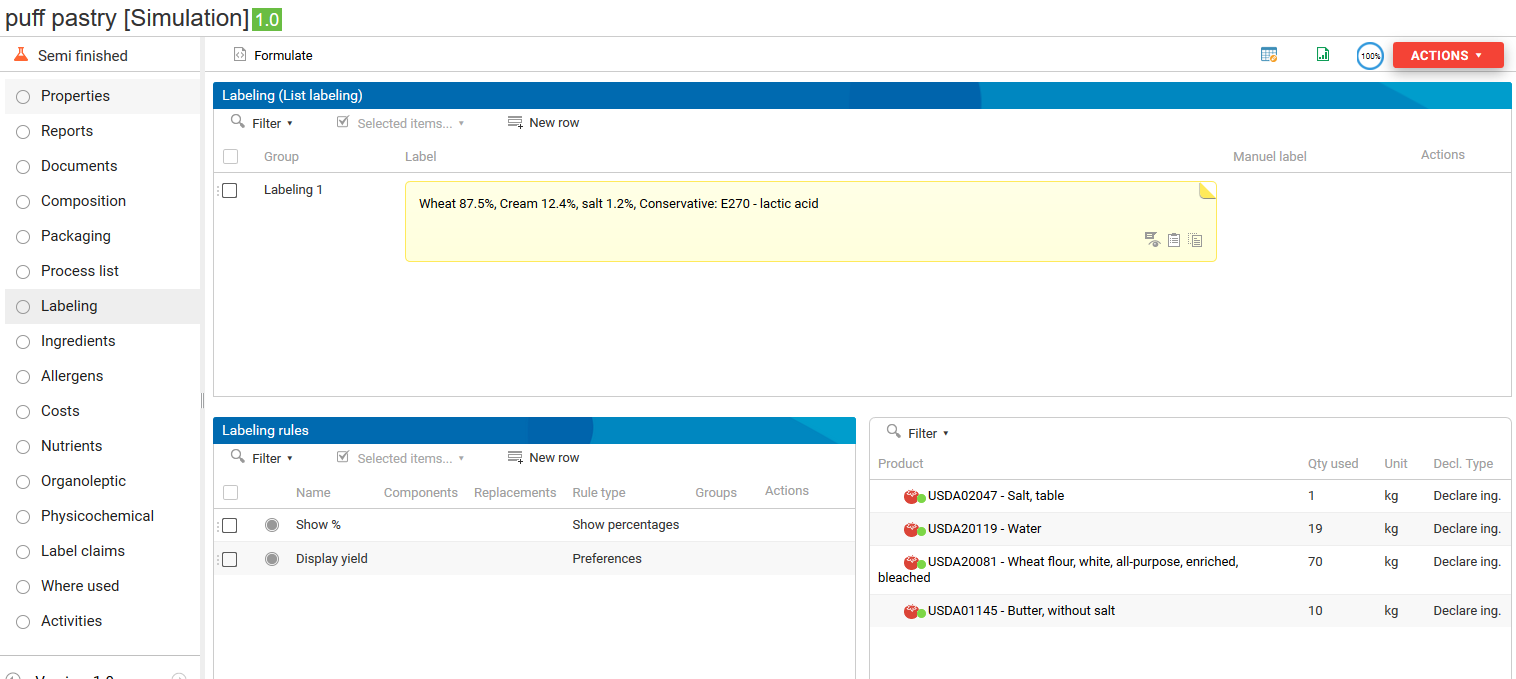

Raw product labeling which doesn’t include the yield:

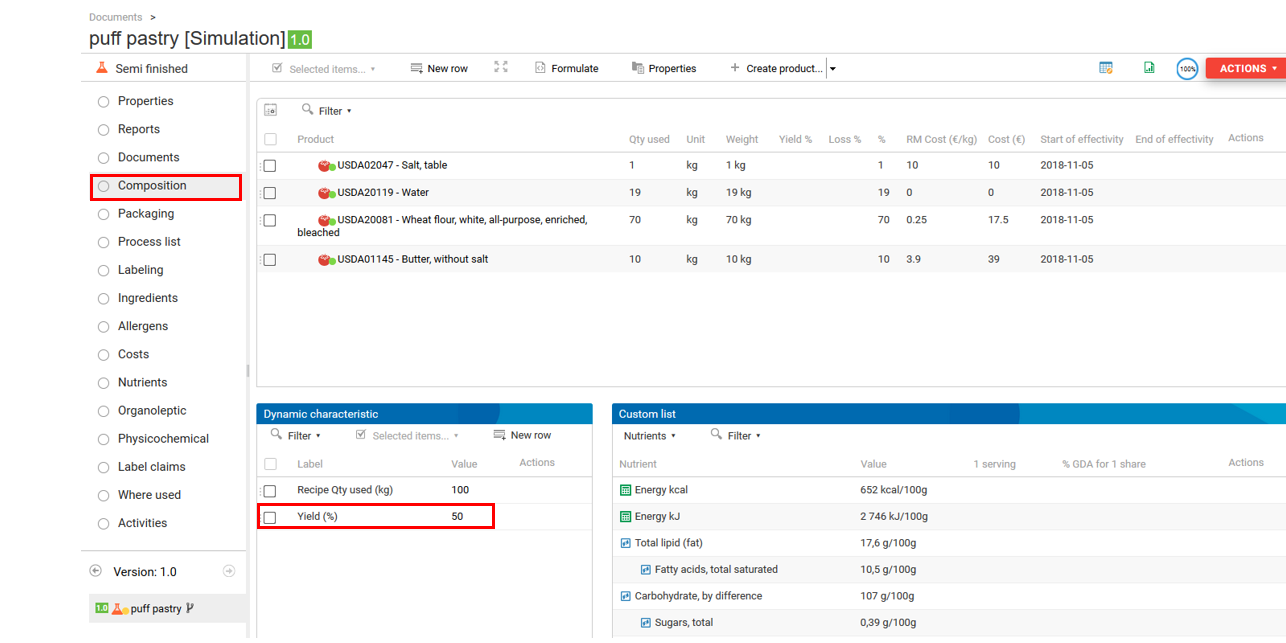

Composition of the cooked product :

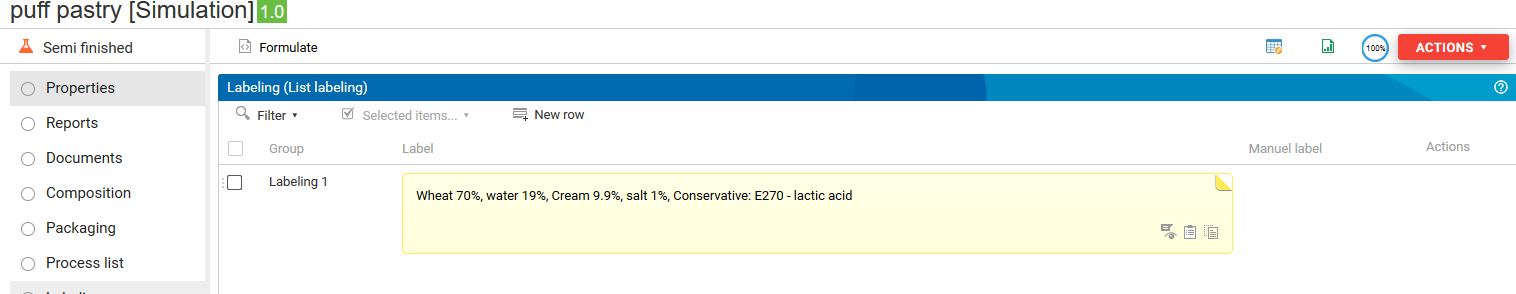

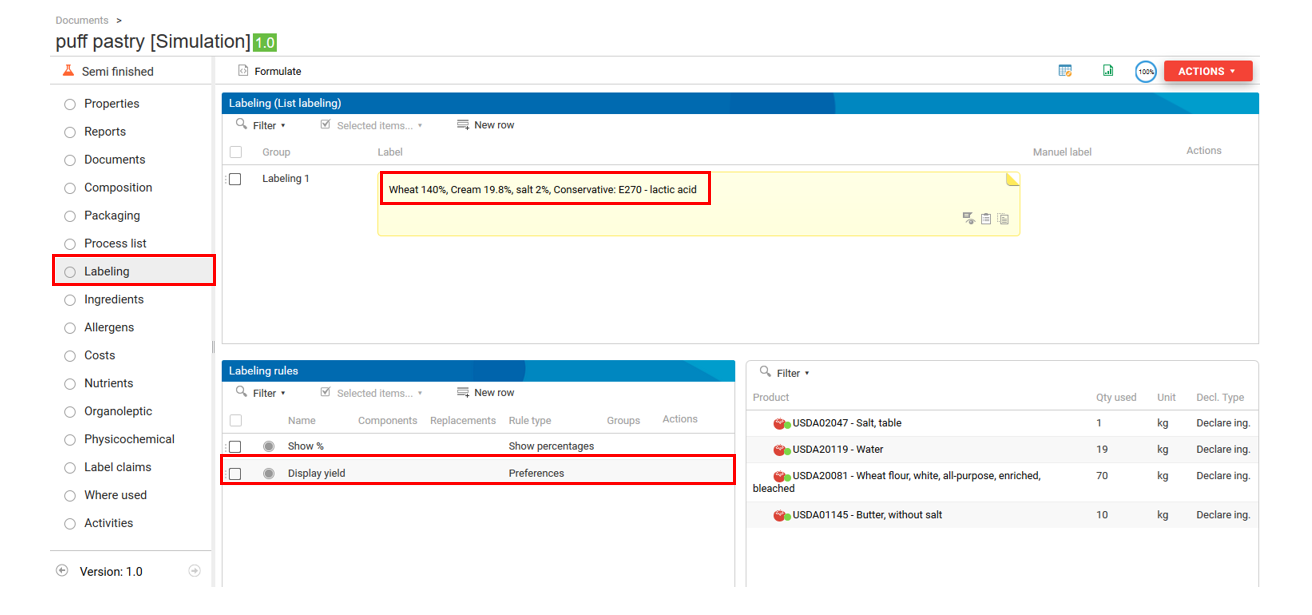

Cooked product labeling which doesn’t include the yield:

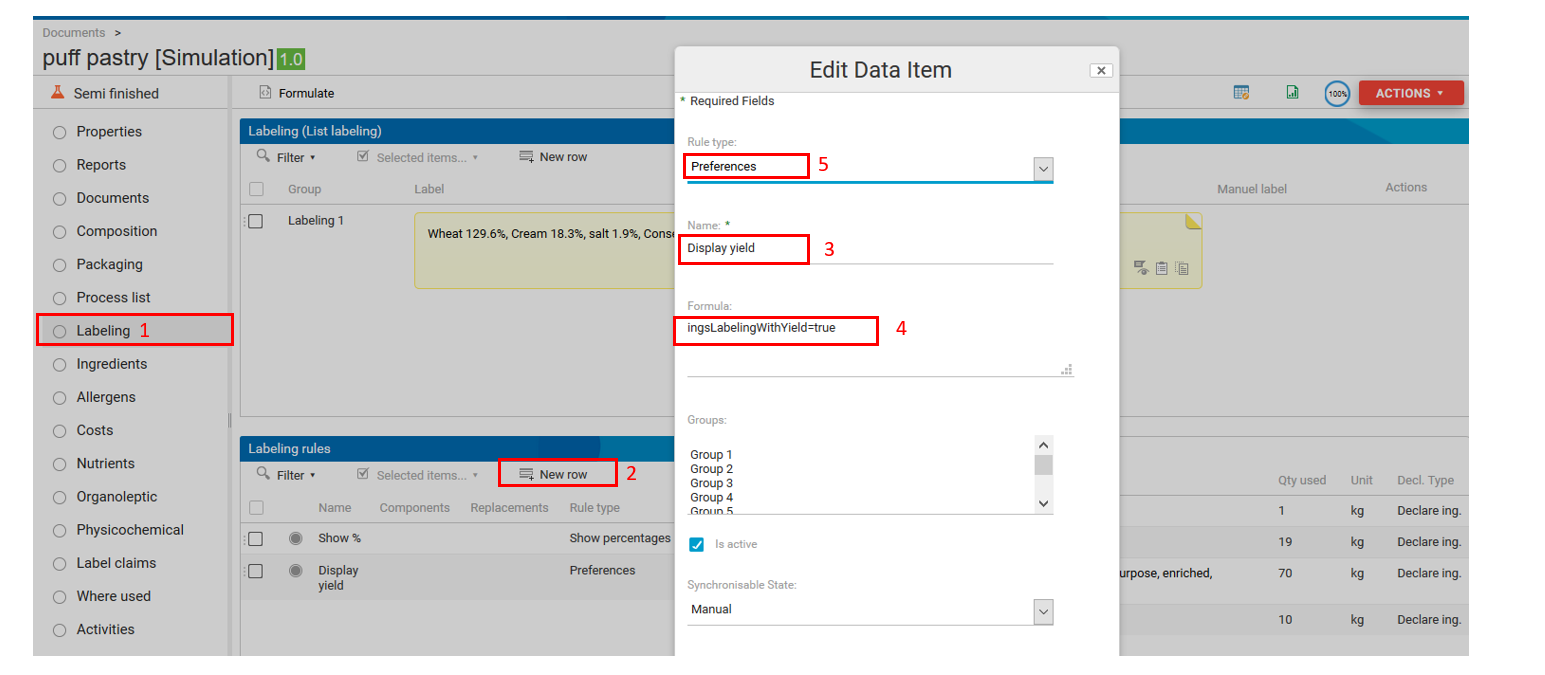

Labeling which takes into account the yield

To take the yield into account when generating the labeling, you must create a rule. For this purpose, go to « Labeling rules » in the list « Labeling » and click on « New Row ». Enter (for example) « Display yield » as a rule name and paste « ingsLabelingWithYield=true » under « Formula ». Then, choose « Preferences » in « Rule type » and click on « Save ». Formulate the product.

In the PLM, a product can be parametrized as cooked or raw by manipulating the yield.

Raw products

In the case of a raw product, the implemented weight is taken into account in the nutritional calculations, physicochemical and labeling. If there is a yield, it won’t affect the calculations.

Cooked products

There exists two cases when products are cooked:

Basic assumption : the product contains the « water » ingredient.

Whether a small quantity of water has been evaporated during the cooking process, the water percentage has discreased and the other ingredients have increased proportionnally so that their sum still equals 100 %.

Cooked product composition:

Cooked product labeling:

Or all the product water has been evaporated but also a small part of the ingredient water content. In this case, there is no more water ; the other ingredients percentages (in which water has not been evaporated) have increased but are still inferior to 100 % and the other ingredients percentages (in which water has been evaporated) have increased and are superior to 100 %.

Overcooked product composition:

Overcooked product labeling:

Regulation about the labeling of cooked products

« For food products which have undergone a humidity loss after a thermal treatment or whatever, the quantity is mentioned in percentages which correspond to the quantity ot the ingredients used, reported to the final product, except when the quantity in question or the total quantity of all the ingredients mentioned on the labeling exceed 100 %. In that case, the quantity is indicated in function of the weight of the ingredients used for the preparation of 100 grams of finished product » [Annex VIII of EU regulation 1169/2011: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32011R1169&qid=1705412174920 ]

Thus, for products which have undergone a loss in water, the computation of their ingredients’ percentages is done like that : [ ( Percentage of the raw product’s implemented ingredient x Raw product weight) ] / (Cooked product weigh)

Alcohol case

Alcohol which evaporates won’t be treated thanks to the yield but thanks to declaration rules by using « Omit » and so on.

Labeling and reconstitution of ingredients

Reconstituting a raw material

Objective: Add a reconstitued ingredient to a recipe (semi skimmed milk: milk powder + water, chocolate powder : cocoa powder + sugar...) and generate its labelling.

Definitions:

Reconstitution rate: *Case n°1: Your calculation of the reconstitution rate is the following:

- Reconstitution rate = Final quantity/ Initial quantity. In that situation, the rate value can be used as such. e.g. Milk reconstitution rate = (20g milk powder + 80 g water) / 20g milk powder = 5

Case n°2: Your calculation of the reconstitution rate is:

- Reconstitution rate = Initial quantity/ Final quantity 100 The value to use is equal to 100/reconstitution rate. e.g. Milk reconstitution rate = 20g milk pwder / (2Og milk powder + 80g water) 100 = 20 So the value you must use is equal to 100/20 = 5.

Reconstitution priority: If an ingredient is limiting: indicate the order of priority if there are multiple reconstitutions using that ingredient. e.g. I have 500g water and I must reconstitute:

- milk for which I need 450g,

- fruit juice for which I need 200g,

In prioritising milk ("1") and in putting a priority of ("2") on the fruit juice, the milk reconstitution will be complete but not the fruit juice reconstitution. We won't reconstitute more than 1/4 of fruit juice (the second reconstitution will be done from the remaining water).

Diluent: Associated ingredient in which we dilute the ingredient on which we work on (in general the quantity of the diluent is superior to the quantity of the diluted).

Reconstituted ingredient: name of the ingredient made of the diluent and the diluted ingredient (water, milk powder), chocolate powder (sugar, cocoa powder)...

How to proceed:

You must add specific fields for the reconstitution in the properties of the ingredient:

- Open the ingredient you want to dilute (=reconstitute),

- In the properties of the ingredient: click on add an aspect

- Select the aspect « Reconstituable (becpg:reconstituableAspect ) »:

- Valid,

New fields are now available in the properties of your ingredient (e.g. milk powder):

If your ingredients don't exist, you must create them in beCPG --> Administration beCPG --> Characteristics --> Ingredients.

Labeling of a reconstituted raw material

Creation of a product containing a reconstituted ingredient:

The reconstitution finally creates a virtual ingredient (without raw material code and only solely linked to your initial raw material). The reconstitution's only impact is on the labeling of your product. If, for example, you create a product such as flavored milk, you create your recipe with:

- the diluted/reconstituted (milk powder)

- the diluent (water)

- the flavouring

If under labelling of your finished product, you choose the option "Declare ingredients" and if you add your reconstituted ingredient to the list of ingredients with their percentages declared (see show percentages rule), you will get the following listing. (note: you can also choose not to declare the percentages of your ingredients).

In the case where the whole diluent, or diluted, is not entirely used, the remaining quantities will be labelled minus the quantity used in their reconstitution.

Labeling and QUID meat

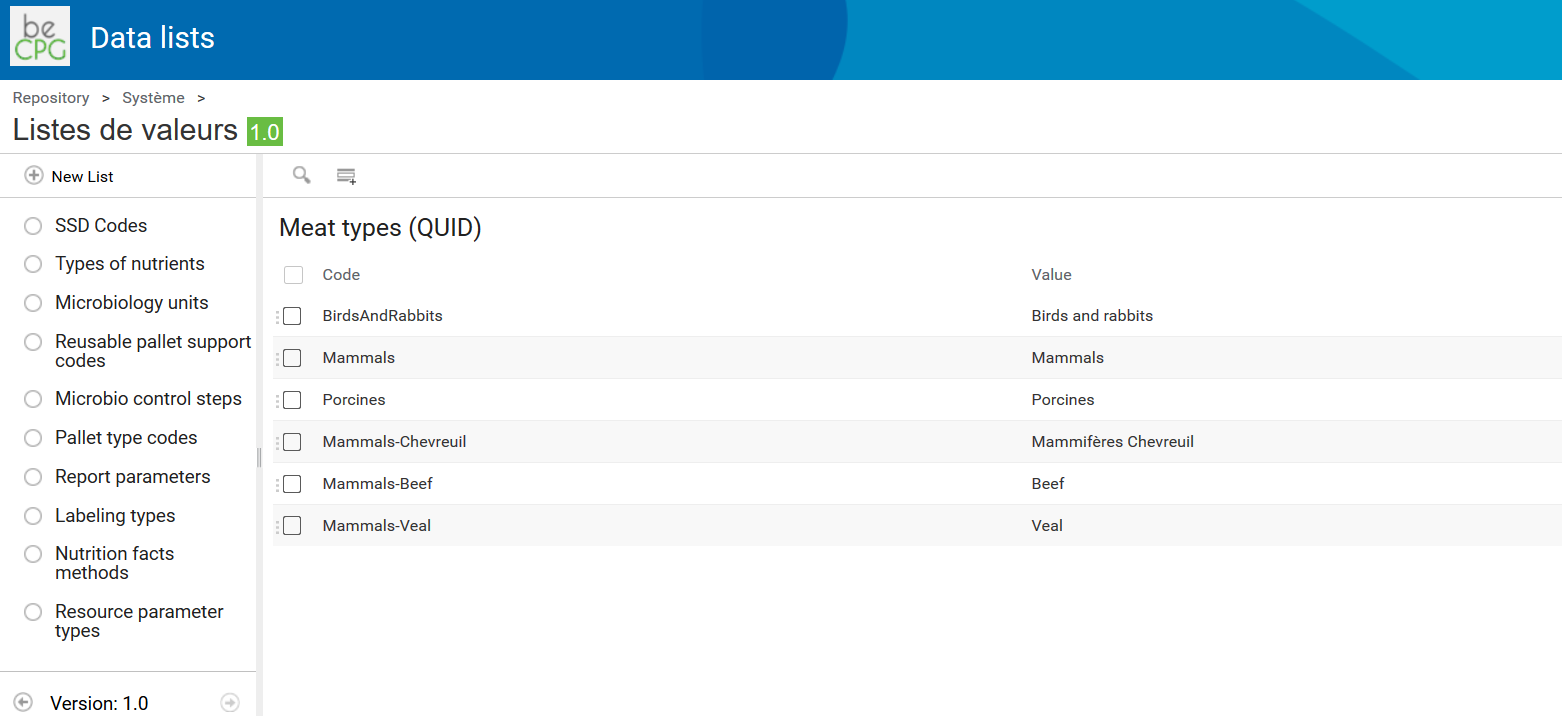

Meat type list (QUID) (list of values)

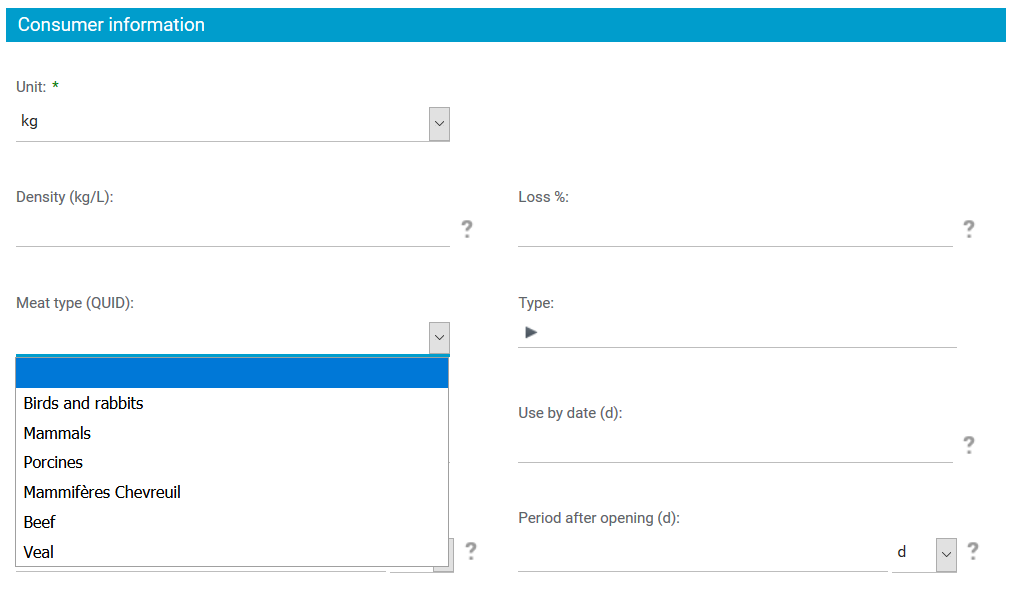

The list of meat is in Lists of Values => Meat types (QUID) By default, three type of meats exist in the system: BirdsAndRabbits, Mammals and Porcines. It's possible to add new elements in this list.

You can add element by clicking on the button "Add new row". Then, enter the code (mandatory for the QUID to work properly). "Main type code"-"code of the new category" (e.g. BirdsAndRabbits-Rabbit) and add the value which corresponds to the name of the category. e.g. Rabbit

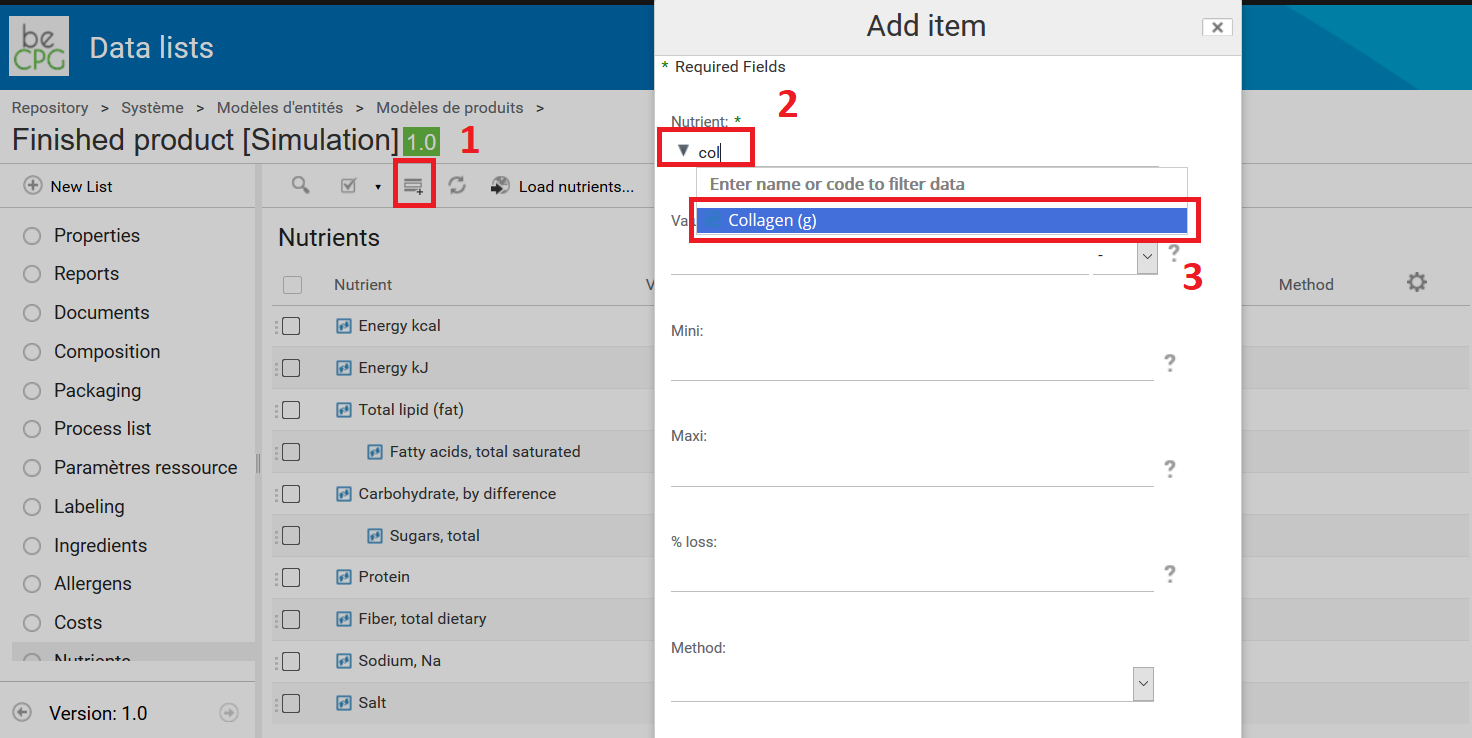

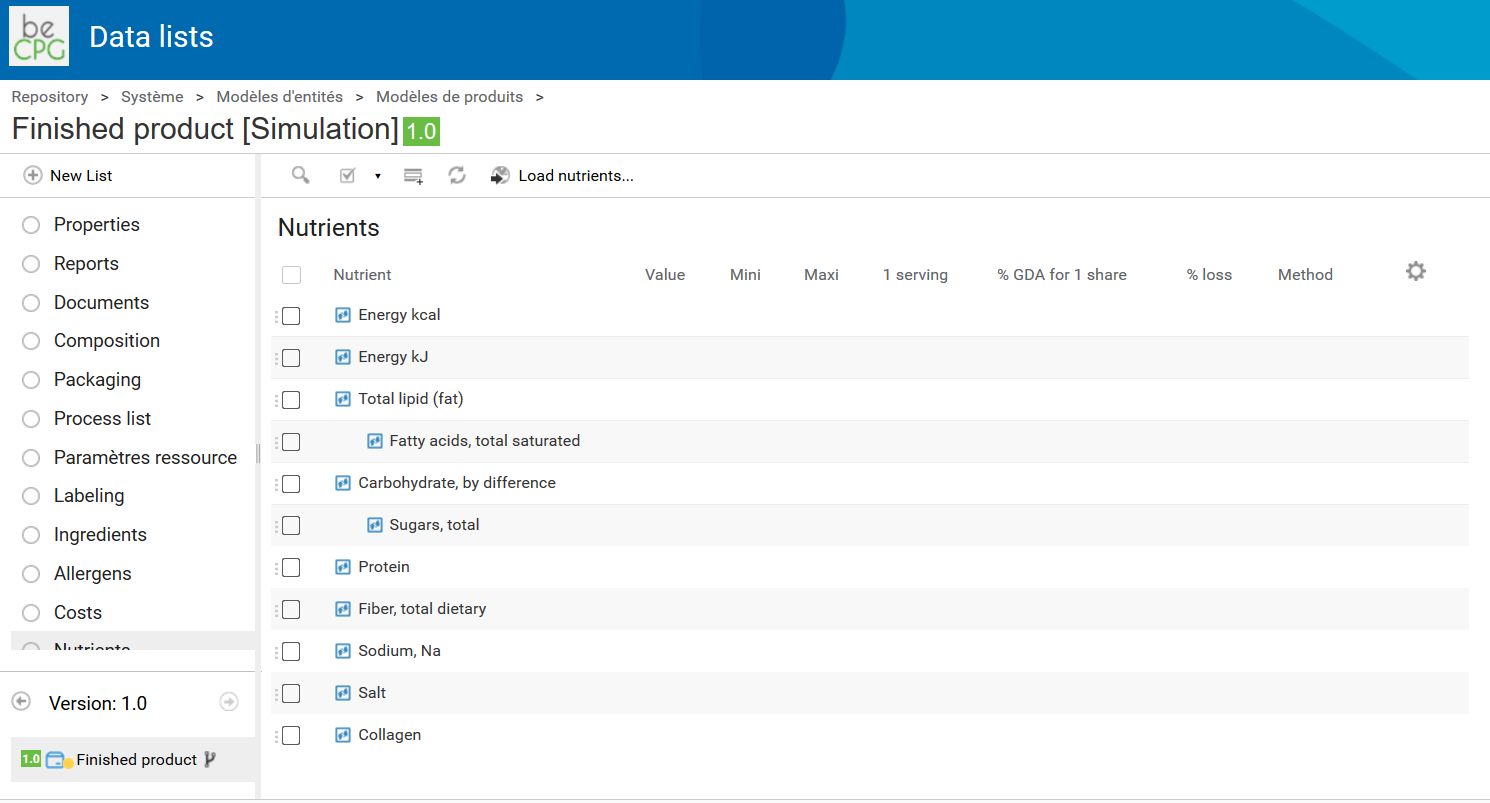

Collagen nutrient

As the collagen will be used for the meat calculation, you must add it to the nutrient list of the:

- Raw material template

- Semi-finished product template

- Finished product template

To do so, go to each product template => Nutrients list => Add a new row and select "Collagen" by entering the first letters.

Select it and click on "Save". Then, collagen is added to your template.

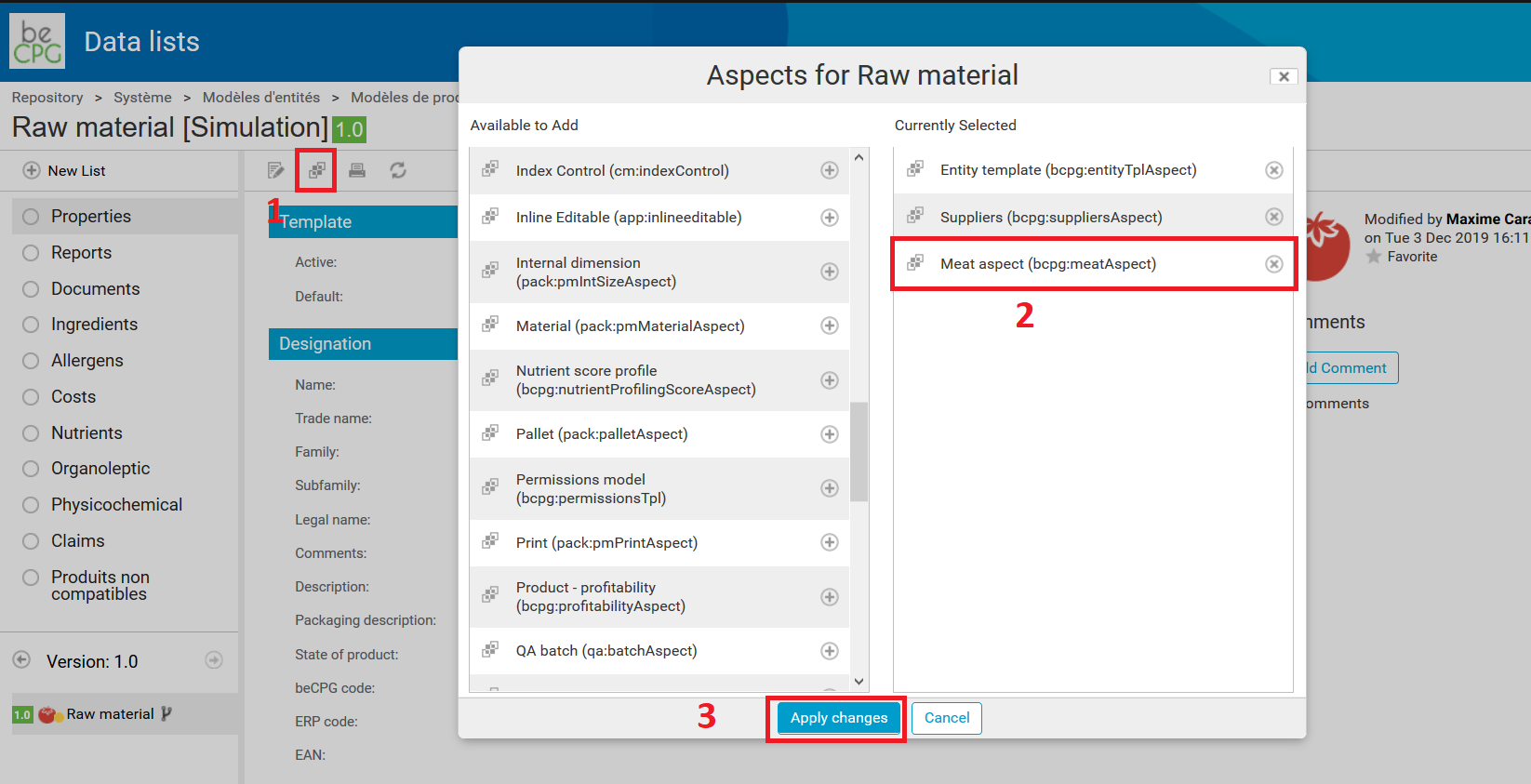

Raw material meat type

This is only for raw materials. Go to the raw material template, and click on Add an Aspect. Then, look for the Meat Aspect (bcpg:meatAspect), select it by clicking on + and Apply changes.

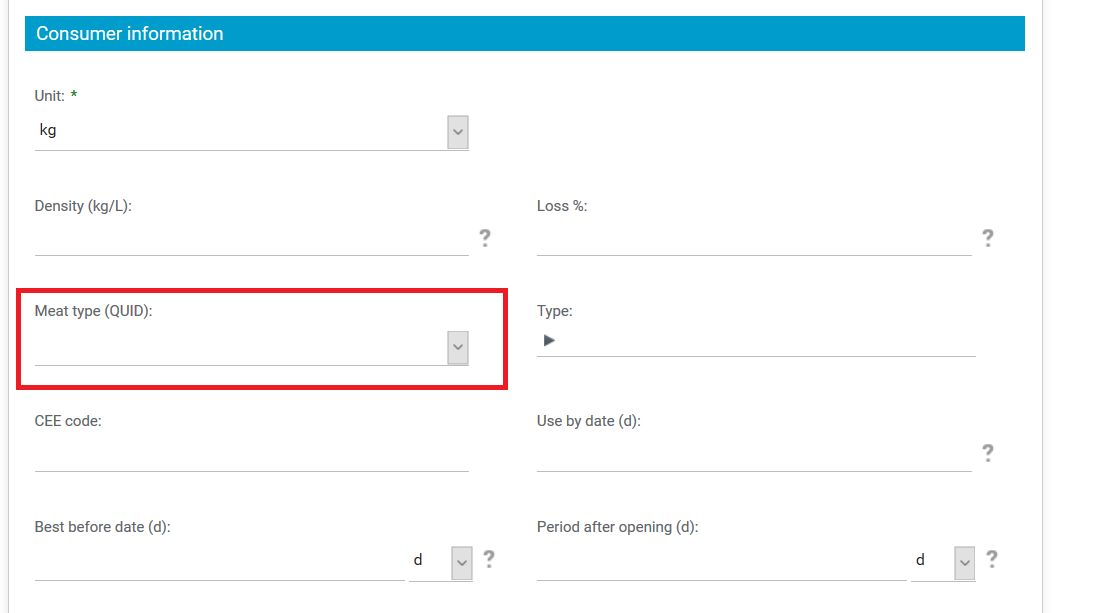

Then, you will have a new field, "Meat type (QUID)" in the Consumer information part of the Properties section.

This field is a dropdownlist, based on the Meat type (QUID) list, previously described.

As a meat raw material will have a QUID meat type, it will be useful as part of a Finished product recipe component to have the information of which meat type the product is made of.

Note: since the version 3.2.0, it's also possible to add this aspect over SF and FP. It's useful if you don't use raw materials.

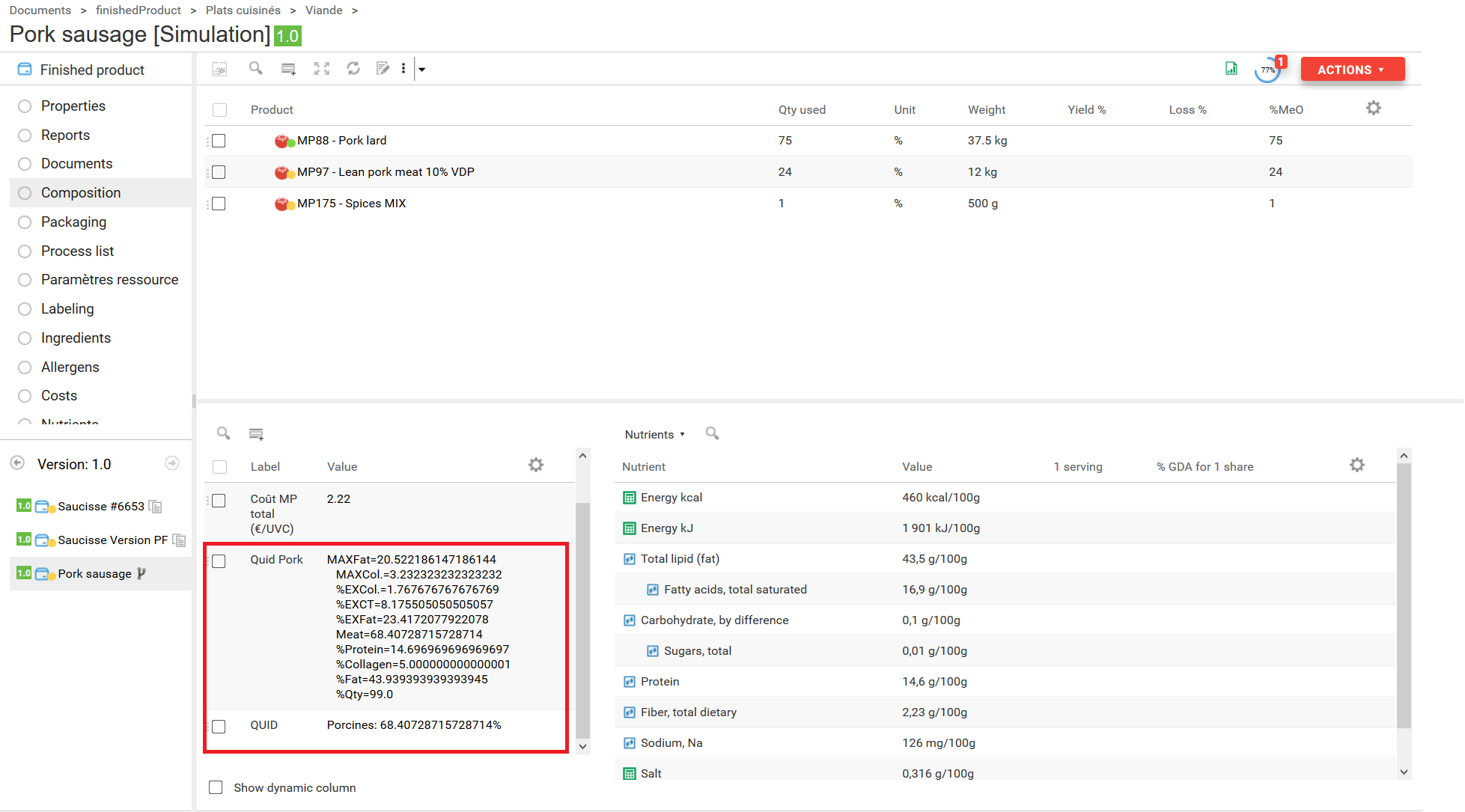

QUID composition calculation

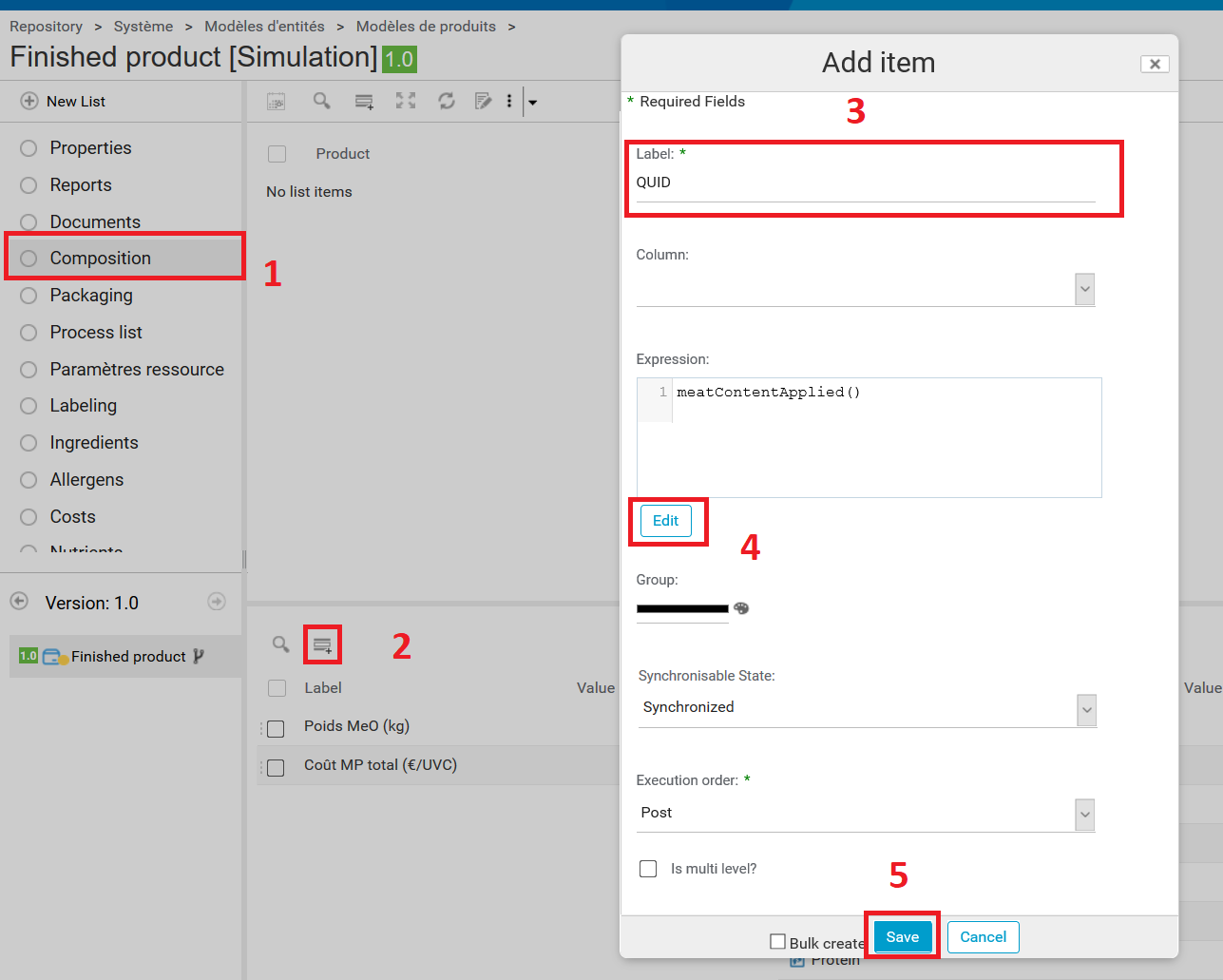

This section is only for finished product, and could also be used on Semi-Finished Product. In the template, you can add two dynamic characteristics. For the "Synchronisable State" of your characteristics, choose "Synchronized" or "Manual". If you choose "Template", the characteristics won't appear on the product.

- To have the % of each meat:

- Label : QUID

- Expression : meatContentApplied()

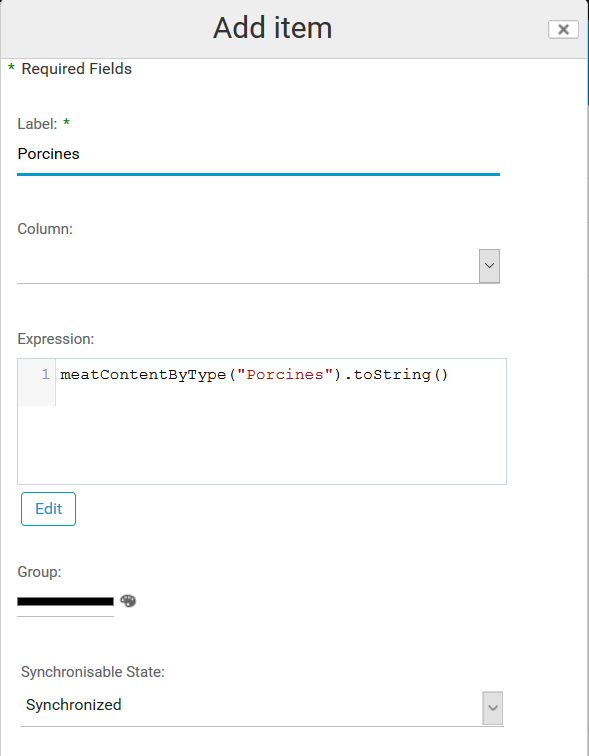

- To have the details of one meat (MaxFat, Collagen, MaxCol, ExFat...):

- Label : {name of meat type}

- Expression : meatContentByType("{meat type code}").toString()

For example, with the type "Porcines":

You can add as much of the detailed meat characteristic as you want. You could also add it directly to the product to not have a detailed QUID for some products, as a template modification will be added to all products.

(Note that those characteristics settings are just for information, and are not mandatory. QUID calculation works fine without.)

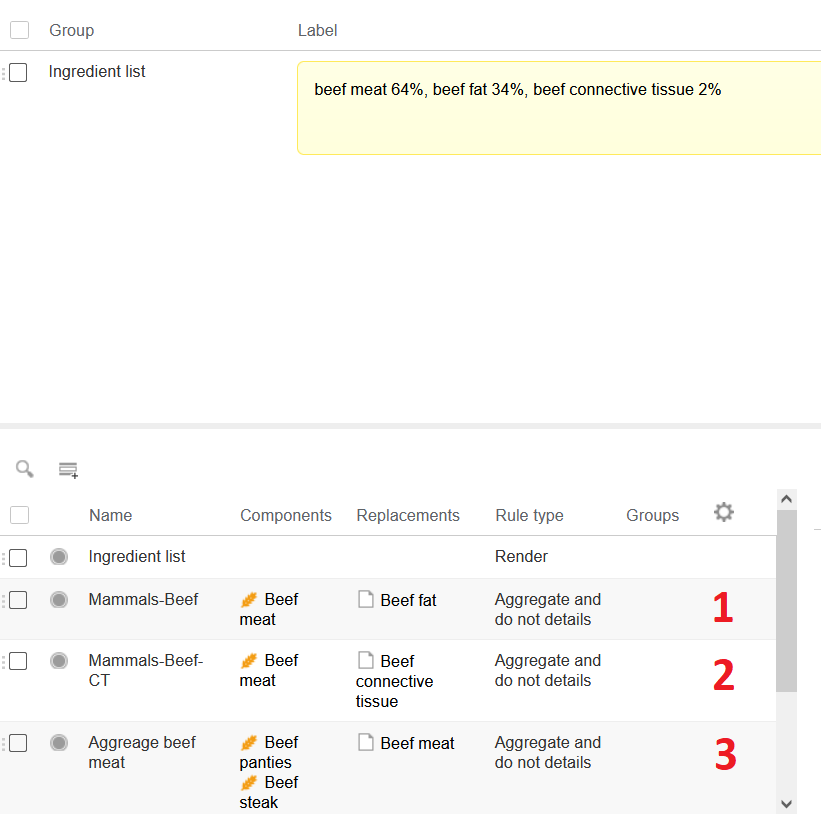

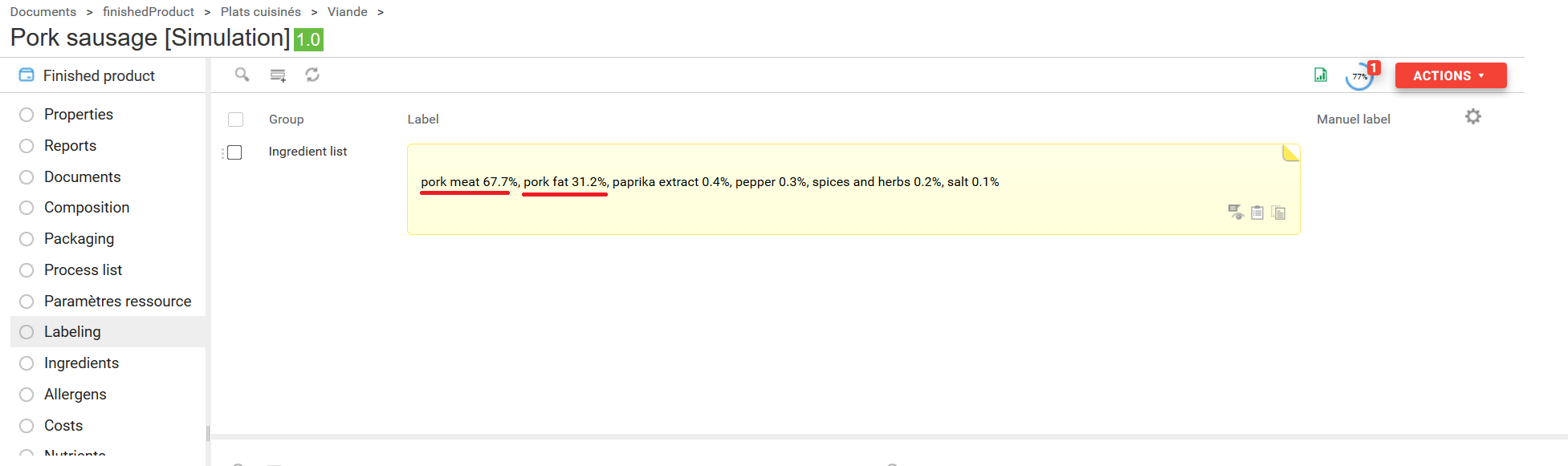

QUID Labeling section

This only concerns Finished product, and could be used also in Semi-Finished product if a label section exists (not by default).

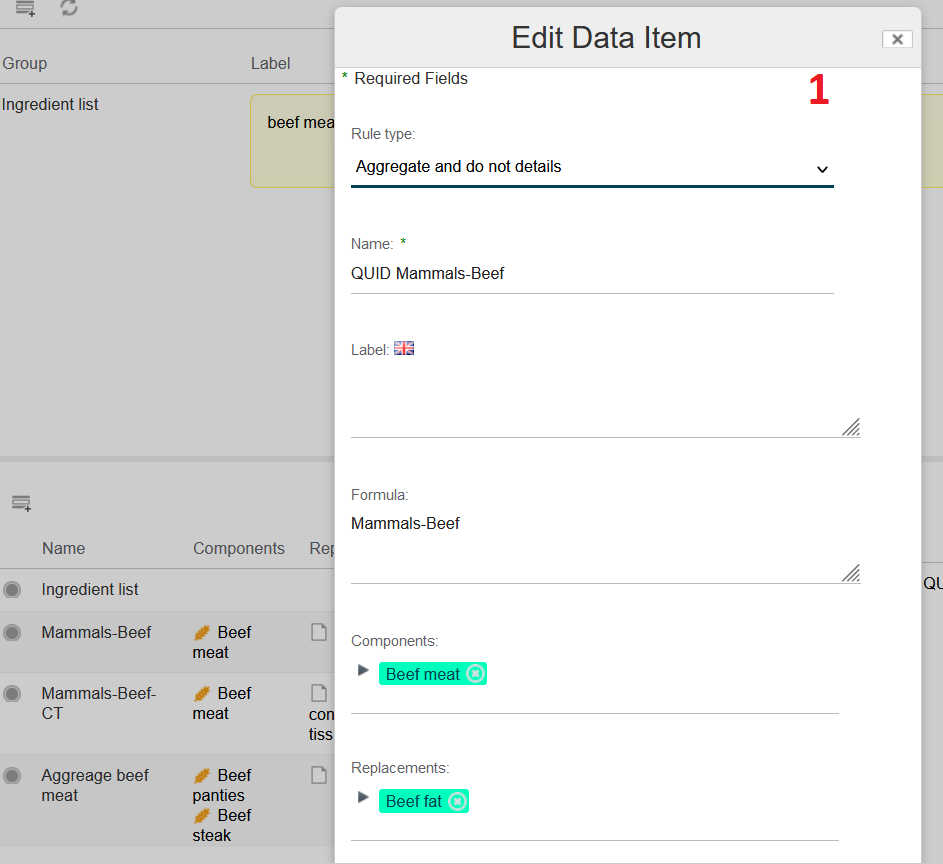

The rule "Agreggate and do not details" is used in three different ways:

- Excedent fat declaration. To allow the system to declare good proportions into the labeling section, depending on the meat and fat quantity to declare per meat type. This rule is mandatory for QUID calculation functionnality.

In the formula, you need to use :

{MEAT_QUID_ID}

Example :

Porcines

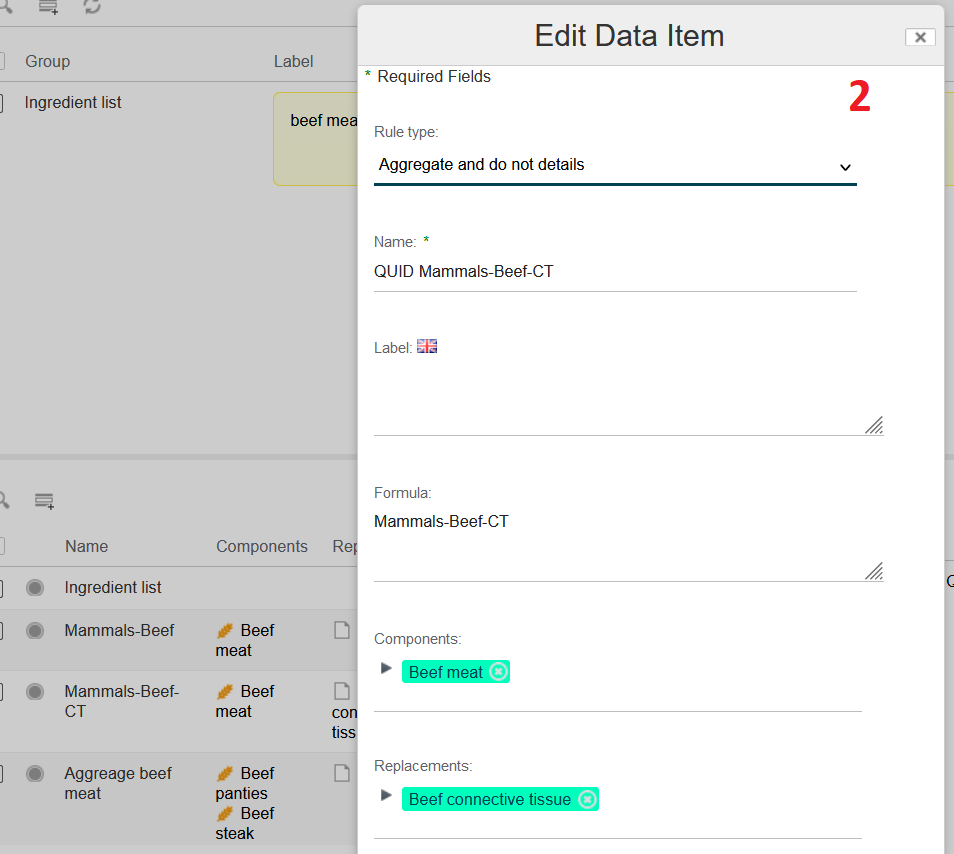

- Excedent connective tissue declaration (available on 3.2 version). To allow the system to declare good proportions into the labeling section, depending on the meat and collagen quantity to declare per meat type. It's mandatory to use this decleration with the fat's one.

In the formula, you need to use :

{MEAT_QUID_ID}-CT

Example :

Porcines-CT

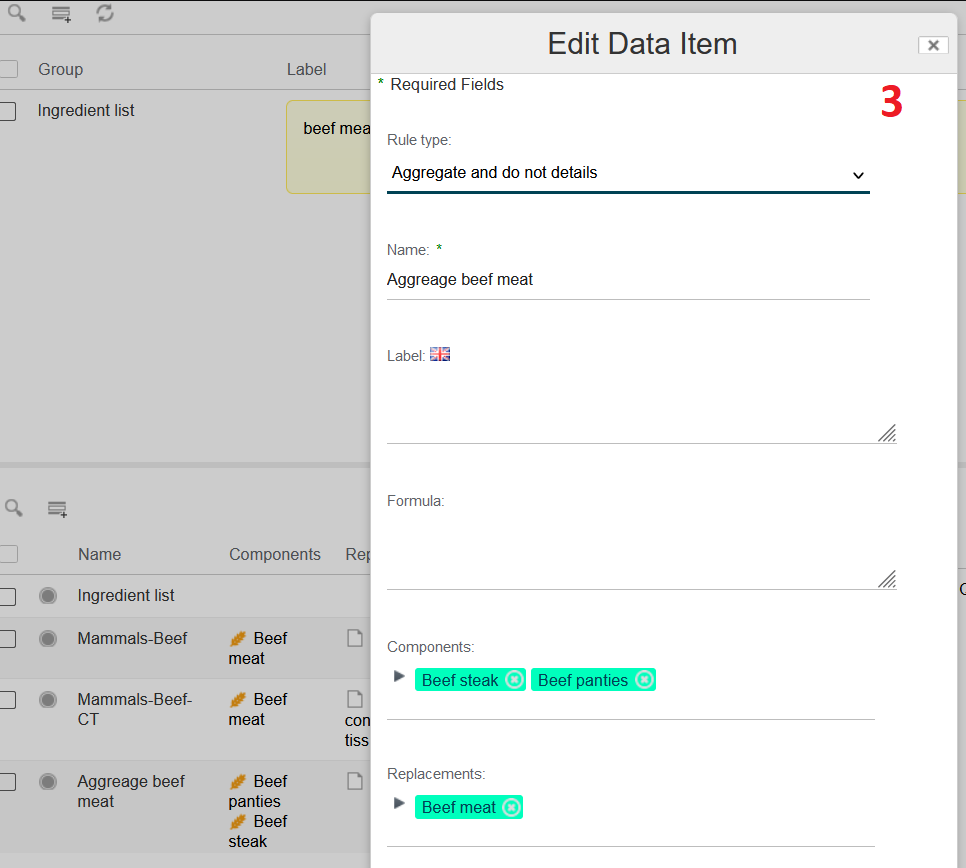

- To allow the system to group different ingredients of one meat type (for example, if you have two raw meats, Pork meat and Pork ham, to be declared as "Porcines") This rule is not frequently used.

QUID Results

Once everything is setting up, you can enter the ingredients you want into the Ingredient sections of your raw material (or SF or PF if you don't use any).

Then, you will be able to see all the meat calculation in 2 differents places:

- Composition, if you have created the characteristics

- Labeling, which is the main aim of the QUID configuration

We strongly advise to set several Finished Product templates for QUID calculation, depending on the use frequency. If you use it almost every time, then you can directly modify the main entities.