Packaging Management

Packaging

For finished products, if the data is specified on the packaging, it's possible to calculate :

- packaging costs

- tares, gross weight and type of packaging for each packaging level

- dimensions by packaging level

- claims, physico-chemical data and limited substances

- materials

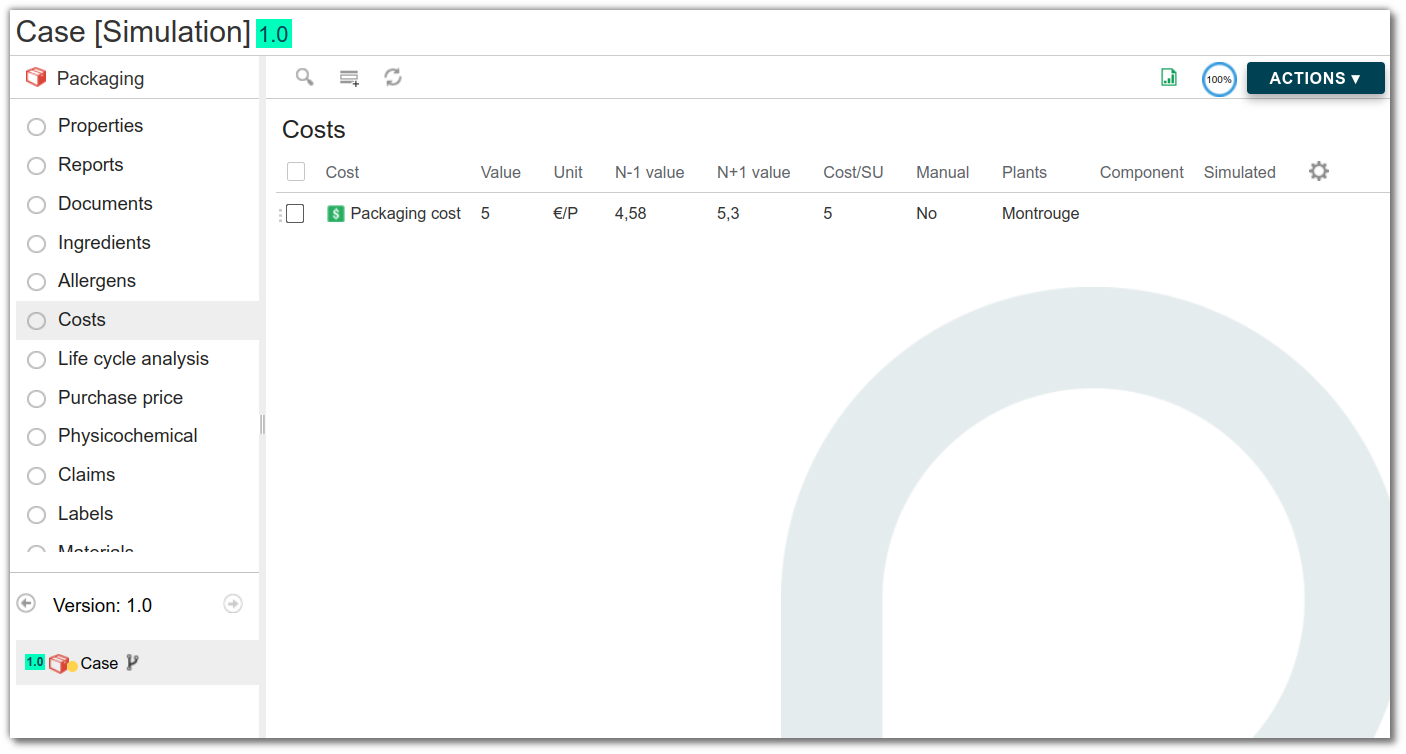

Cost

Two lists are available to manage your packaging costs:

- The cost list for a simple calculation Click here for more information on costs.

In this list, indicate :

- the price of the packaging in the "Value" column, and its unit in the "Unit" column

- the "N-1" and "N+1" values, which refer respectively to costs in previous and subsequent years

- "plants", to link the cost to a factory

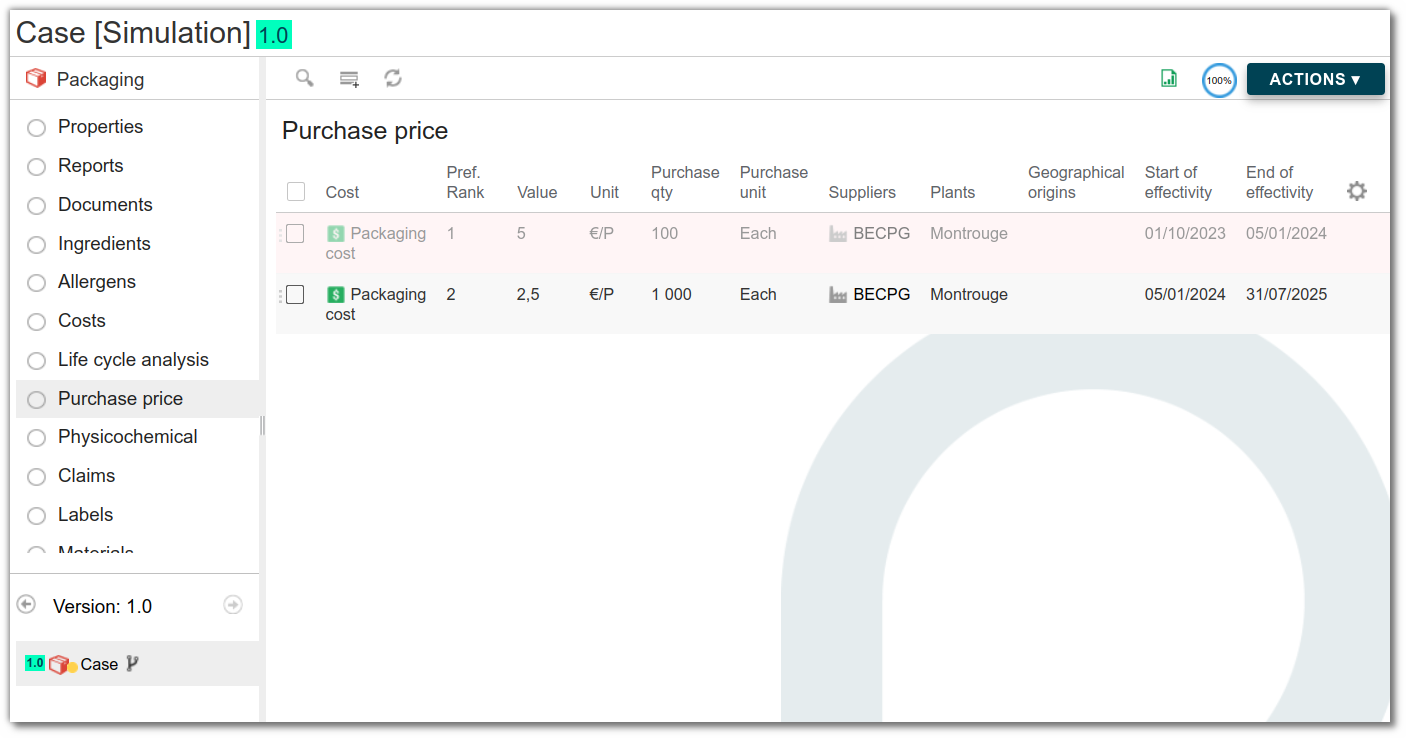

- Purchase price list in the case of advanced calculations

In this list, in addition to the data already present in the cost list, fill in :

- costs linked to purchase volumes, year or supplier

- cost hierarchy

- cost start and end dates

- geographical origin

Example: buying 100 boxes will not cost the same as buying 10,000 boxes.

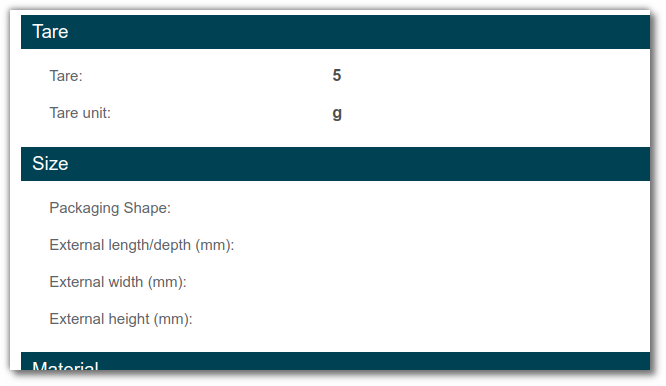

Tare and gross weight

The packaging tare corresponds to the weight of the packaging. It is used to calculate the gross weight of finished products. The formula for gross weight is :

Gross weight = net weight + packaging weight

e.g.: for packaging in metres, the tare corresponds to the tare for 1 m..

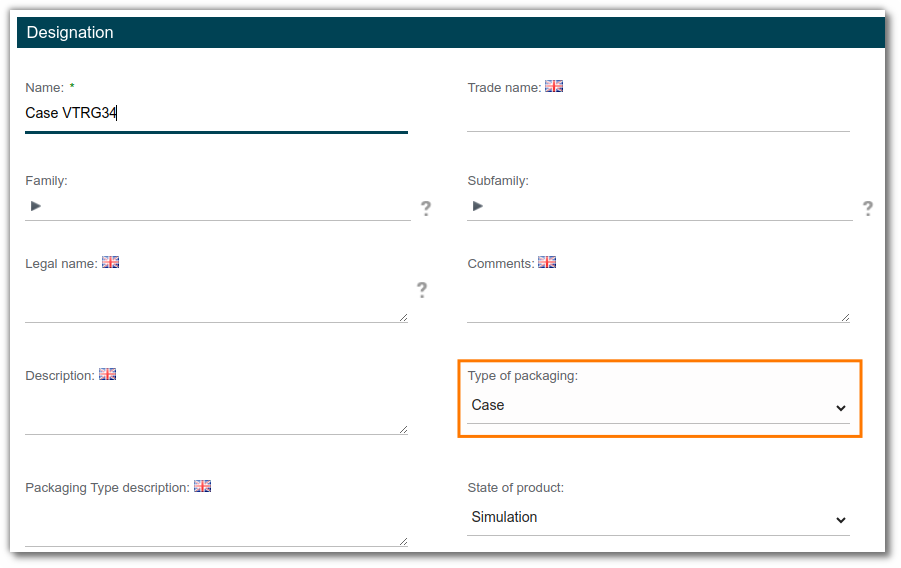

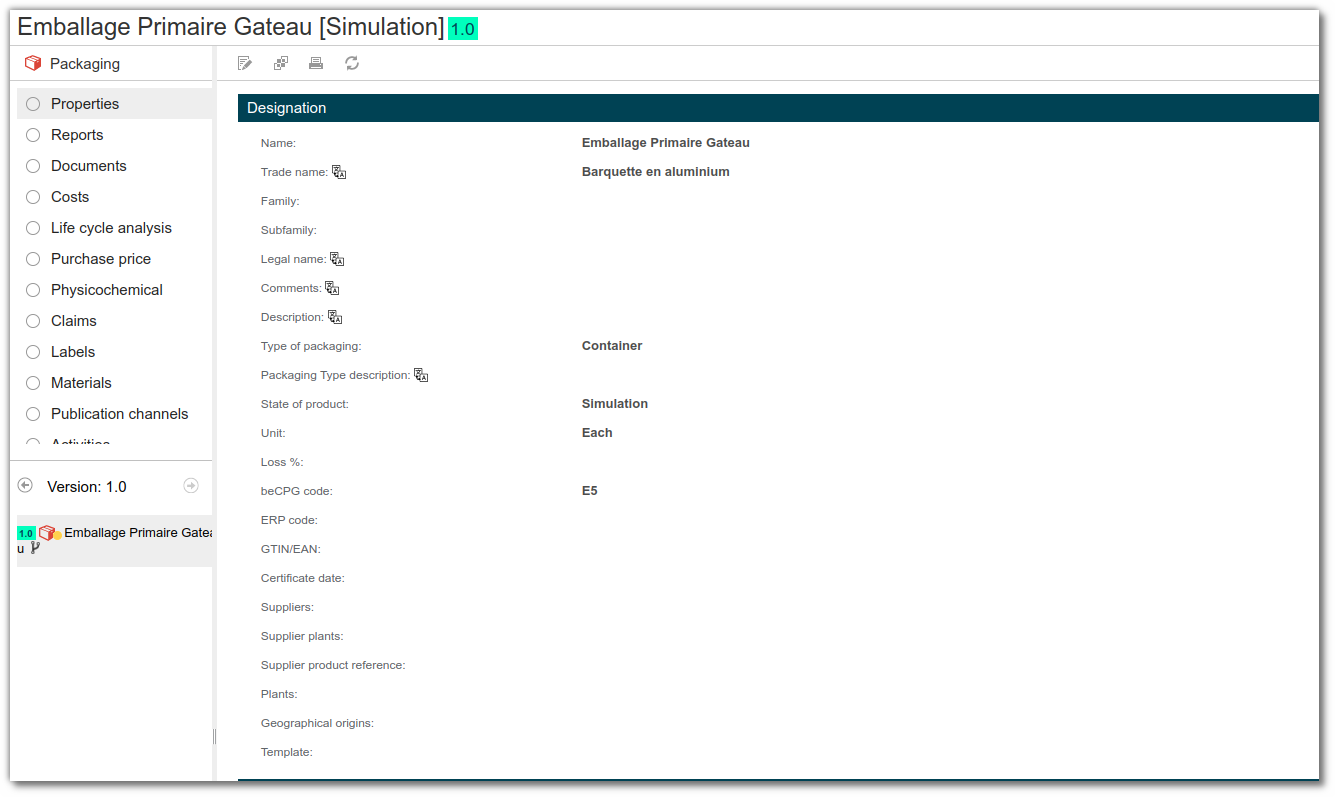

Type of packaging

The packaging type is a drop-down list in the Packaging Properties section, giving a short description of the packaging.

The drop-down list is initialized with GS1 values. It can be customized in beCPG administration Click here for more information.

NB: If the packaging is master on its level, this information is inherited on the finished product in the "Packaging" tab.

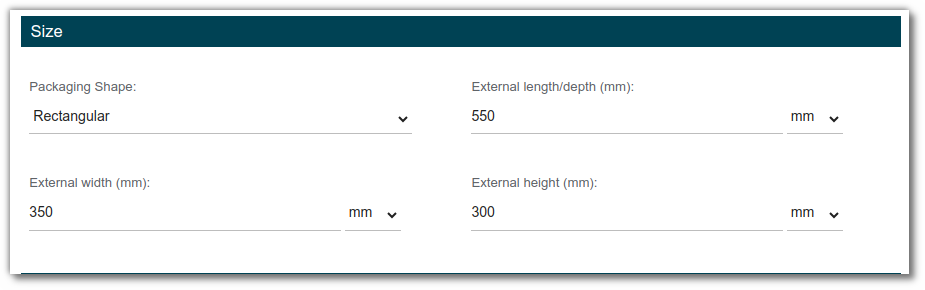

Size

The Size section of the Packaging Properties list allows you to enter the external length, width and depth.

These sizes are inherited by the finished product if the packaging is considered a master on its level.

If the Size section is not present, add the aspect on the Packaging entity model Click here for more information

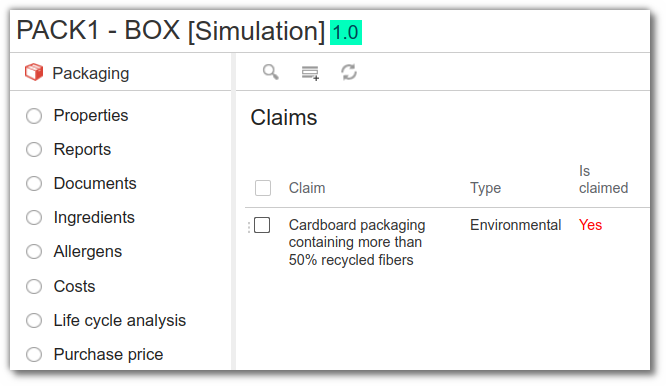

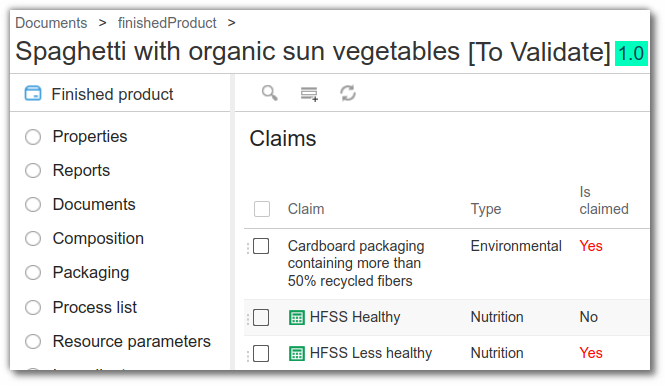

Claim

The Packaging claims list is used to enter data relating to the packaging law:

- Packaging with at least [x%] recycled content”.

- Mostly recyclable packaging

- Fully recyclable packaging

- Compostable packaging

- Reusable packaging

- SVHC-free packaging > 0.1% m/m

- Packaging free of hazardous substances > 0.1% w/w

- Packaging without endocrine disruptors

They spread to the finished product if the claim is added.

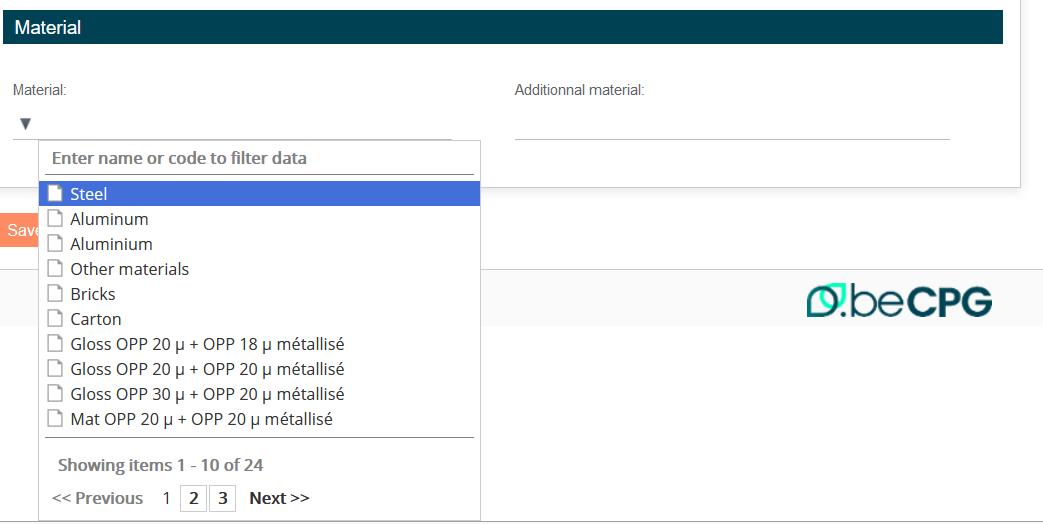

Packaging materials

The packaging materials formulation provides a list of packaging materials and their weights for each finished product. The drop-down list of materials is initialized with CITEO values. It can be customized in beCPG administration. Click here for more information.

There are two possible solutions for packaging:

- The Material section, in the case of single-material packaging.

In the Material section of the packaging properties, you can enter the type of material used in the packaging.

Please note that the "Additional material" field is a free text field that will not be considered in the formulation.

If the material section is not present, add the aspect on the Packaging entity template. Click here for more information

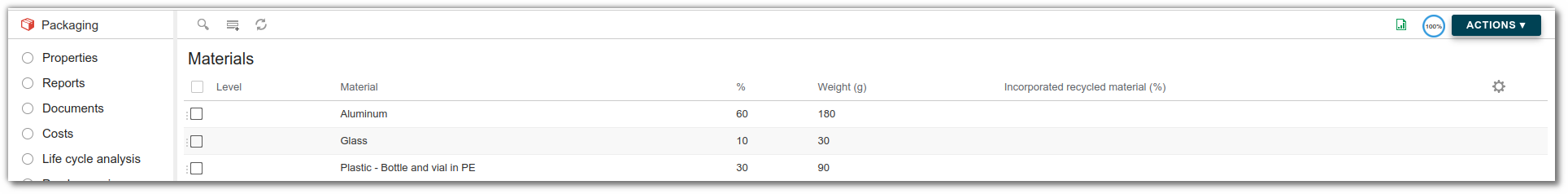

- Material list, in the case of multi-material packaging. The Material list must be added to the packaging entity model.

Formulation of the Materials list

On the finished product, add the Material list to the entity template, to view a summary of the materials used. Depending on use, it may also be important to add the list for semi-finished products and packaging kits.

If an entity (finished product, semi-finished product or kit) contains packaging with materials (in the Material section or list) then the entity's Material list is formulated taking into account per material :

- Material

- Percentage (%) of presence in the packaging

- quantity : based on the packaging tare weight and it's percentage of presence in the material or it can be added manually

- incorporated recycled material (%), in the case of recycled materials used.

Recyclable materials

On the packaging Materials list, you can add recyclable materials:

To determine whether a material is recyclable or not, you need to tick the ‘Is not recyclable’ box in the Packaging material value list.

Note : to add materials to the administration Packaging material value list Click here

Management of recyclability rate and percentage of recycled material incorporated into materials

On the Physicochemical list for packaging, it is possible to enter data :

Total recyclability rate: used to assess the recyclability potential of a packaging.

- It is the ratio of the total weight of recyclable materials in the packaging to the total weight of the packaging.

Percentage of recycled materials: used to assess the quantity of recycled material incorporated into the packaging.

- It is the ratio between the weighted percentage of recycled material incorporated into the packaging and the total weight of the packaging.

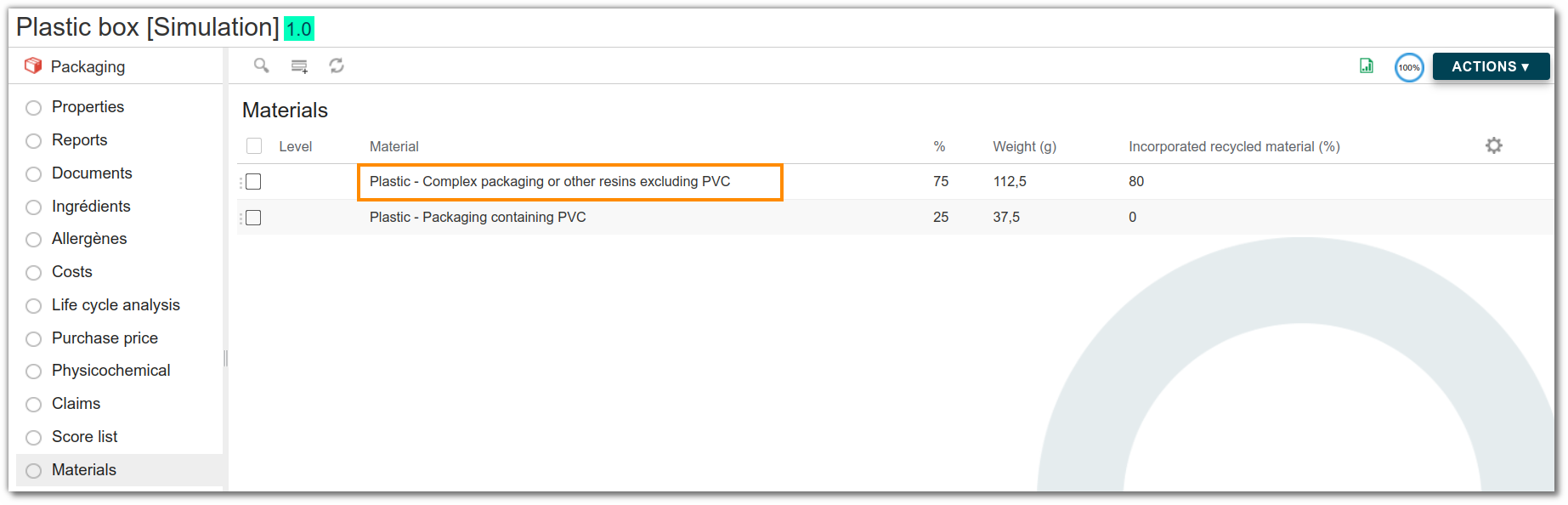

Example : for a 150 g plastic box composed of:

- 50% of recyclable PP rigid plastic (75 g), 80% of which is recycled material

- 25% of recyclable PET plastic (37.5 g), 60% of which is recycled material.

- 25% of plastic containing non-recyclable PVC (37,5 g).

The Total recyclability rate is : (75 + 37.5) × 100/150 = 75% and the Percentage of recycled materials is : (75 x 80 + 37.5 x 60)/150 = 55%. This packaging is therefore 75% recyclable and contains 55% recycled material.

Note : on the finished product, as the Materials list is formulated, these two physico-chemical characteristics are also calculated. The calculation includes the quantities of primary, secondary and tertiary packaging per pallet.

Management of packaging recyclability

According to the AGEC legislation, a product or packaging can be described as ‘Mostly recyclable’ if it meets the following 5 criteria:

- Accessible collection (It can be collected efficiently throughout the country, thanks to collection points close to the population).

- Effective sorting (It can be sorted and sent to a suitable recycling facility).

- No disruptive elements (It contains no substances or materials that disrupt sorting or recycling or limit the quality of the recycled material).

- Effective recycling rate ≥ 50% (Recycling processes must enable more than 50% by mass of recycled material to be obtained in relation to the waste collected).

- Real and viable industrial recycling (Recycling must be carried out on an industrial scale, and the quality of the recycled material must be sufficient to guarantee sustainable use by industry (guaranteed outlets).

If, in addition to the above criteria, the effective recycling rate ≥ 95%, the claim ‘Fully recyclable packaging’ may be used.

Example: For a 150 g plastic box composed of:

- 75% recyclable plastic, so 112.5 g.

- 25% non-recyclable plastic, so 37.5 g.

The effective recycling rate is therefore : (112,5/150)x100 = 75%. This is more than 50%, and given that the other 4 points are implicitly validated, the words ‘Mostly recyclable packaging’ is claimed. This statement can be found on the packaging Claims list.

Packing of finished products

beCPG classifies product packaging into 3 levels.

Primary level

Generally referred to consumer sales unit (CSU) packaging. This may be the CSU itself, but more often it's a grouping of consumer units into a "commercial" batch (example: a carton pack of 12 plain yogurts). This level covers the minimum quantity of product that can be purchased by the customer. It will be eliminated by the final consumer.

Secondary level

This is a grouping of intermediate groupings of CSU for easy handling by distributor or point-of-sale operators (example: American case). The most common secondary levels are

- cardboard

- plastic seal

- plastic crate

- easy-open or flapped cardboard boxes

- boxes or flow-packs (heat-shrink plastic film) for grouping during promotions

- cardboard label

- scotch tape

- spacer

Tertiary level

This corresponds to logistics variant packaging. This packaging is used to transport large quantities of products to stores or manufacturers. The most commonly used tertiary levels are :

- transport crates (american crates)

- pallet

- shrink film

- pallet labels, etc.

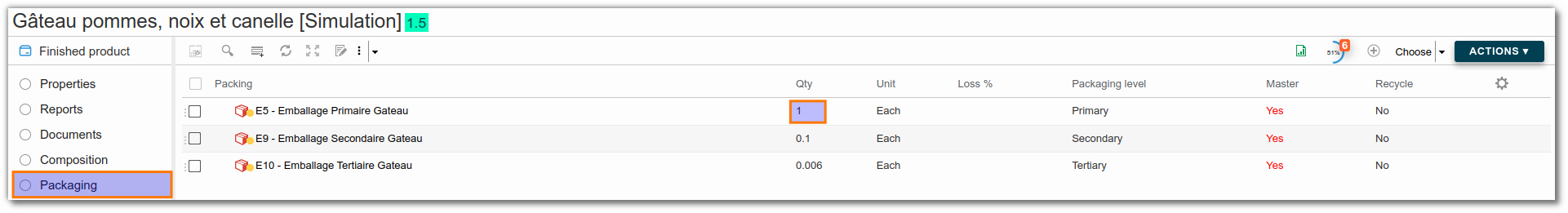

Packaging list

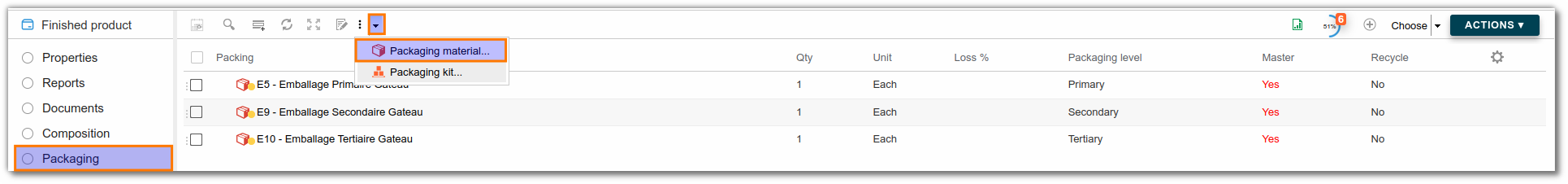

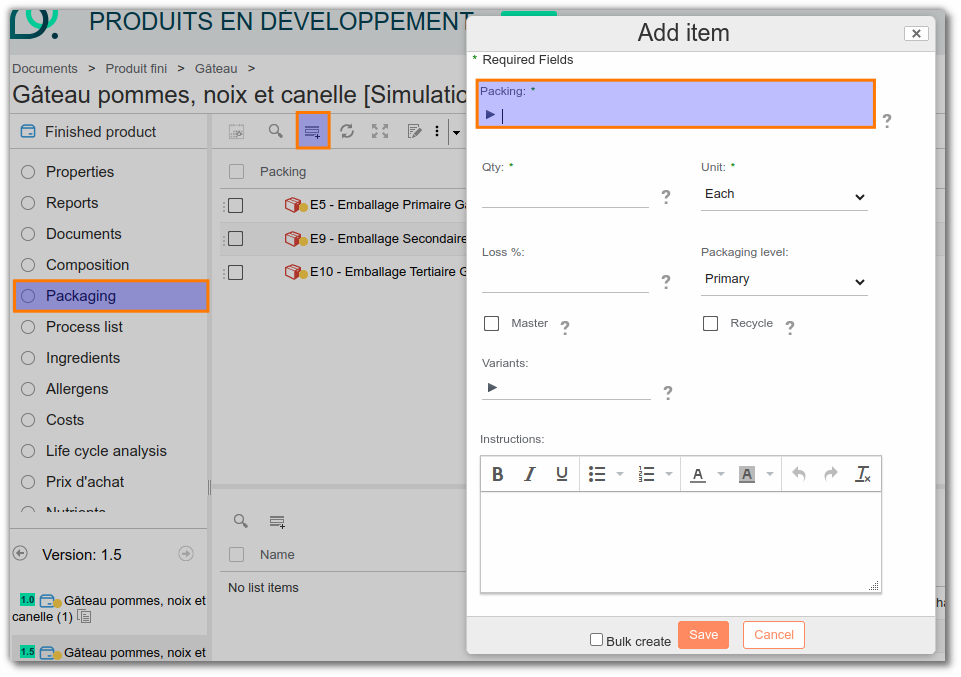

Add packaging

To link packaging to a product, first click on the Packaging list.

- if the packaging does not exist in beCPG, click on the arrow to the right and select "Packaging material". Then enter the name (mandatory field), description and unit, and click on "Save".

- if the package exists in beCPG, click on "Add" to select a package already created.

You can then navigate within each package by simply clicking on it.

You can then access the properties and various lists linked to the packaging in question.

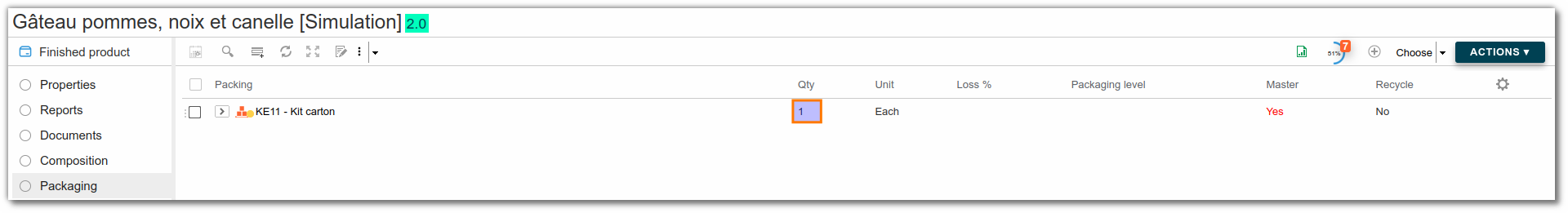

Register quantities

In the column "Qty" enter the quantity of packaging for a finished product.

If the finished product is:

a CSU, then quantities must be entered for 1 CSU. e.g. A Brick of Soup.

- Primary: 1p brick

- Secondary: 0.1 p cardboard = 1 cardboard /10 bricks ( 1 cardboard being composed of 10 bricks)

- Tertiary: 0.006 p Pallet = 1 pallet / ((1 cardboard /10 bricks) x 16 cardboard/pallet)

a cardboard, then quantities must be entered for one cardboard. eg: A carton of soup brick.

- Primary: 10p bricks (1 cardboard is composed of 10 bricks)

- Secondary: 1p cardboard

- Tertiary: 0.0625p Pallet = 1 pallet/ ( 1 cardboard x 16 cardboard/pallet)

In the "Unit" box, select the unit corresponding to the quantity previously chosen. This unit can be "Piece", "m", "kg" or "m²".

Note: If the following fields are completed: “Number of products / case” & “Number of cases / pallet”, then the quantities must be completed in levels. They will be divided by the value entered.

- In the case of: a CSU, quantities must be entered for 1 CSU.

*e.g. One Brick of soup

- Primary: 1 brick

- Secondary: 1 cardboard & Number of products / case: 10

- Tertiary: 1 p Pallet & Number of cases / pallet = 16

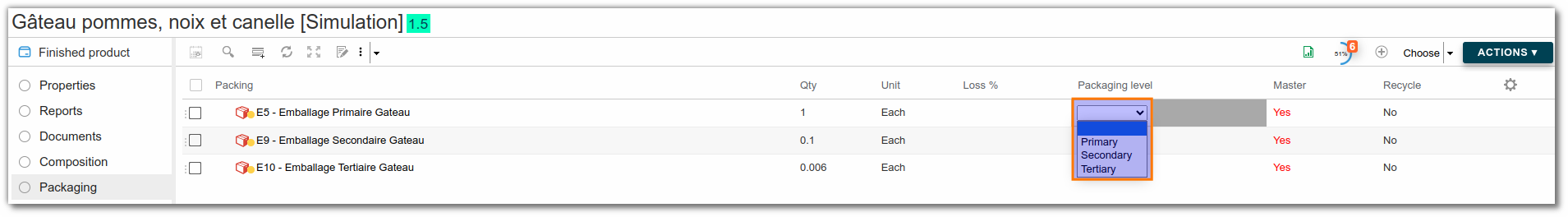

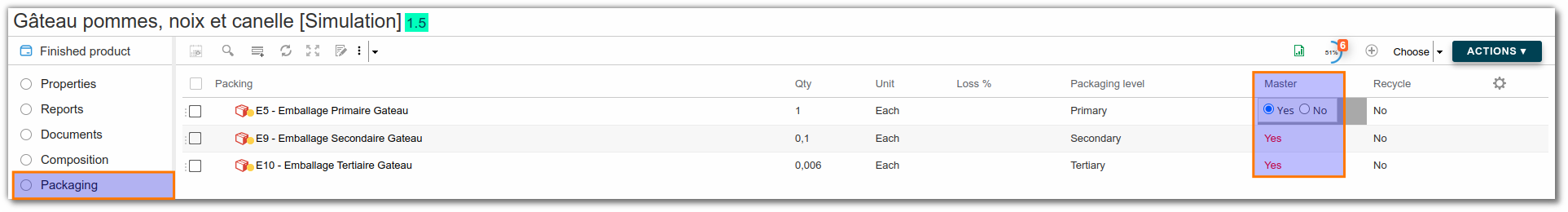

Master packaging on its level

In the "Packaging level" box, enter the packaging level: primary, secondary, tertiary, according to the description of the latter (described above).

Indicate in the "master" column the packaging with the largest dimensions. The finished product will then inherit information relating to this packaging (shape, type, name or dimensions). This avoids to enter the dimensions of each product, as the master package's dimensions are used.

example: Brick of soup

- Primary: The soup brick

- Secondary: The cardboard containing the soup bricks

Tertiary: The pallet

In the absence of a master packaging on a level, pack dimensions can be entered manually on the product's "Packaging" tab. example: Use of a plastic film which can have variable dimensions depending on the product.

If the dimensions of the CSU are greater than those of the packaging (e.g. chicken), add the "Dimensions on finished product" aspect to manually fill in the "Length/Width/Height" fields.

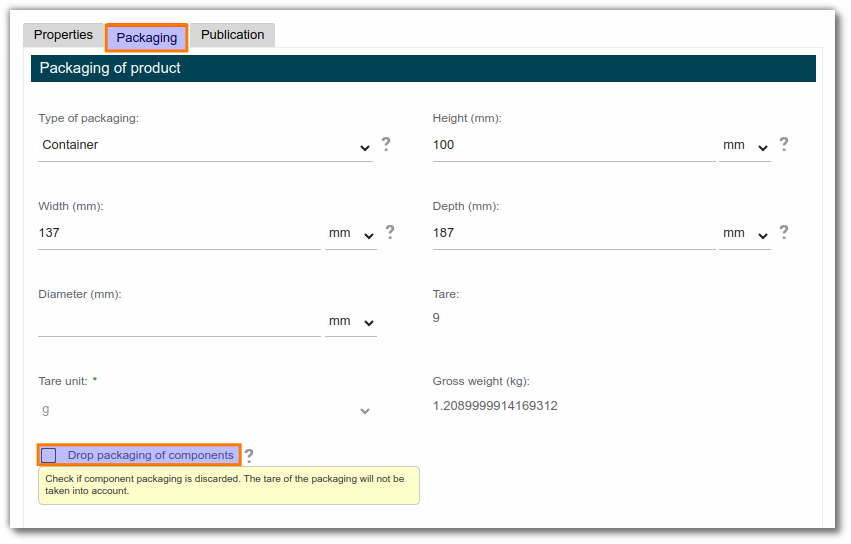

Discarding Packaging of components

A function is available in the Finished product properties list to drop the packaging of composition elements.

Drop the packaging means ignoring the packaging tare value added on the composition elements (e.g. the packaging of a semi-finished product), while retaining the costs associated with the packaging.

The Packaging Kit

Packaging kits group together a number of primary and/or secondary and/or tertiary packaging items. They are very useful in two cases:

Packaging grouping: packagings are common (qualitatively and quantitatively) to several products. example: there are 3 packaging kits for 1000 finished products.

Register palletizing data: palletizing is similar for several finished products. *example: pallet height, number of layers, number of cartons per layer.

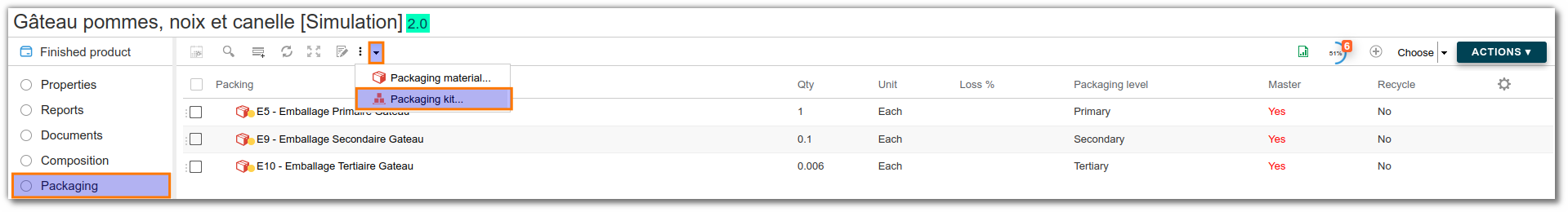

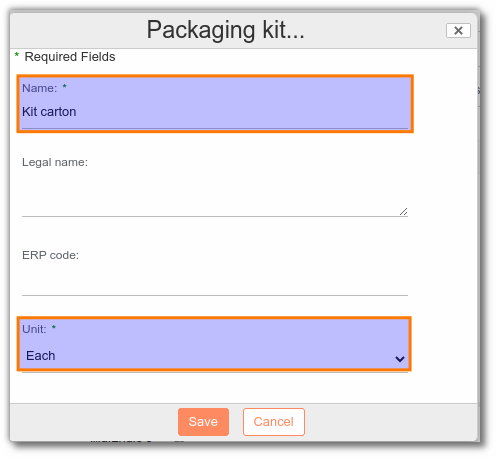

Add a packaging kit

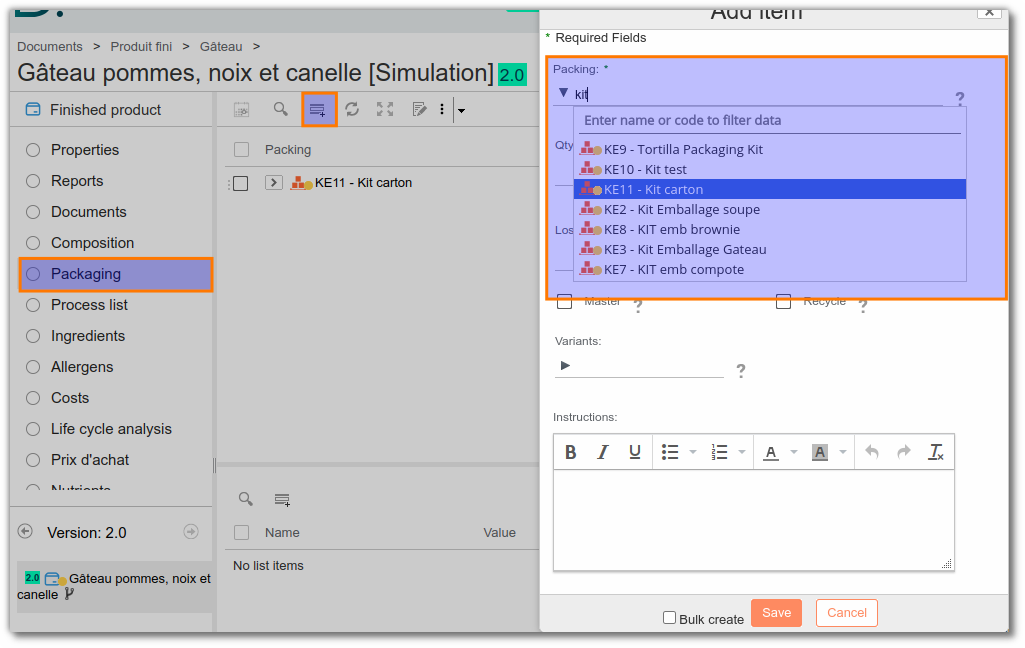

To link packaging kits to a product, first click on the packaging list.

If the packaging kit does not exist in beCPG, click on the arrow to the right and select "Packaging kit". Then enter the name of the kit (mandatory field), the description and the unit, and click on "Save".

If the packaging kit exists in beCPG, click on "Add" to select the packaging kit already created.

Packaging grouping kit

The packaging kit is the equivalent of the semi-finished product for packaging. First, add the packaging to the packaging kit, then a piece of this kit to all the finished products that use it.

Palletizing kit

The palletizing packaging kit enables palletizing data to be entered directly into the packaging kit. The finished product linked to this kit will inherit a wide range of information (number of products per package, number of packages on the pallet, etc.).

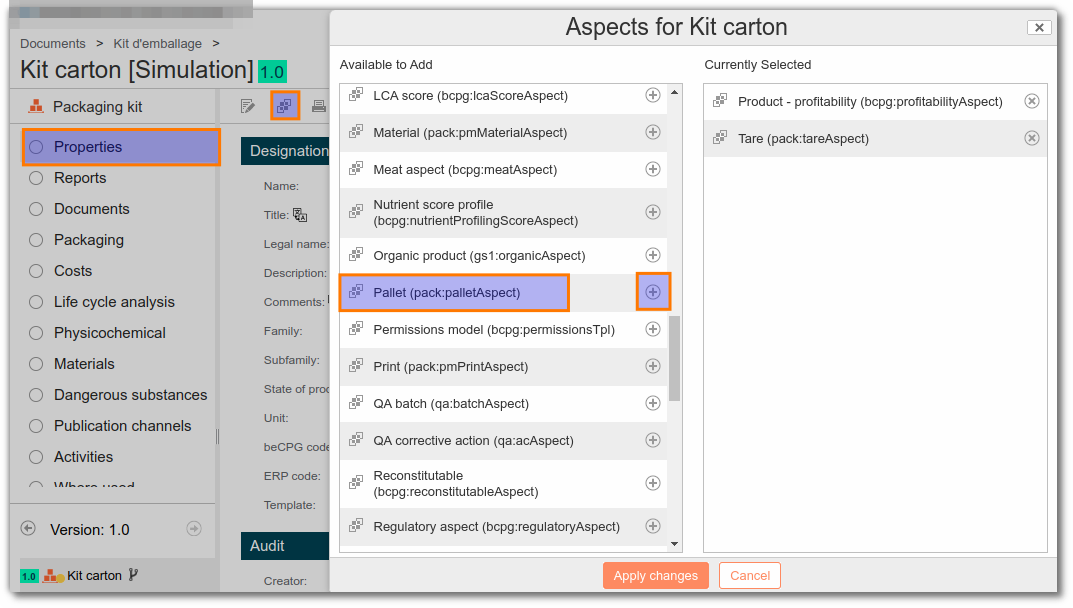

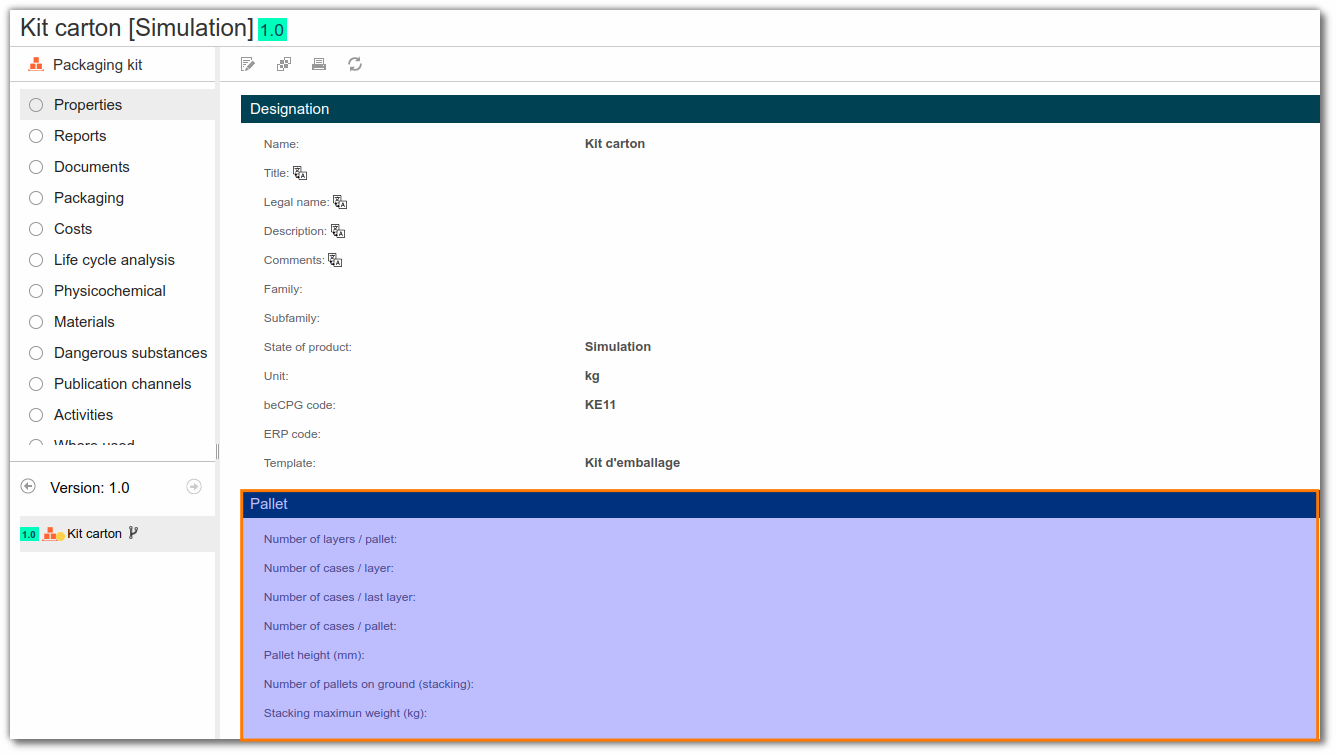

Add palletizing aspect on finished products template and packaging kit The palletization aspect lets you specify the number of packages per pallet, the number of layers per pallet and the number of packages per layer. It can be added by going to the Properties tab and clicking on "Add aspect", then selecting "Palletization".

New properties are then available on the palletizing kit:

New properties are then available on the palletizing kit:

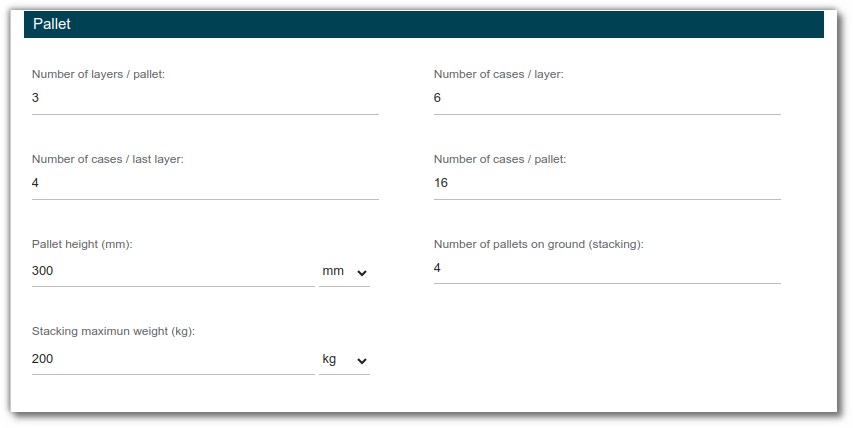

Complete information on palletizing packaging kit To complete them, click on "Edit" properties. You will then have access to the kit designation data (name, description, etc.).

For the Pallet data, you will need to fill in :

The number of layers per pallet example: 3.

The number of packages per layer (on a pallet) example: 6.

The number of packs in the last layer of the pallet example: 4.

The total number of packages per pallet example: 6x2 + 4 = 16.

Add packaging In the "Packaging" list, enter secondary and tertiary packaging.

Add the Palletizing Packaging Kit to the list of finished product packaging. The packaging kit is added to a product at the secondary level, with the unit "Product per package ". The value of the quantity in the list will be recognized on the product as the value of Products per package. All kit information will then be formulated on the product in the palletization information.

Note: In the absence of a kit with this configuration, palletizing data can be added manually on a product-by-product basis.

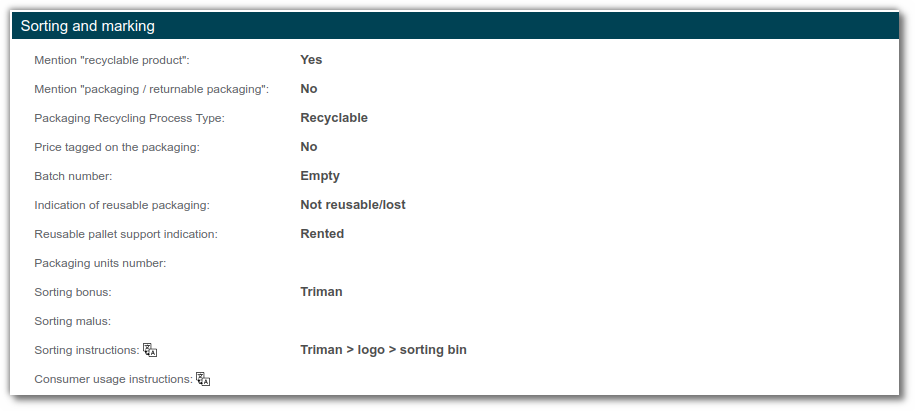

Sorting instructions

In beCPG, it is possible to store information on sorting instructions in the “Sorting and marking” section of the packaging or finished product. There are also Sorting Bonus and Sorting Malus fields to store information on premiums and penalties paid by the producer to its eco-organization.

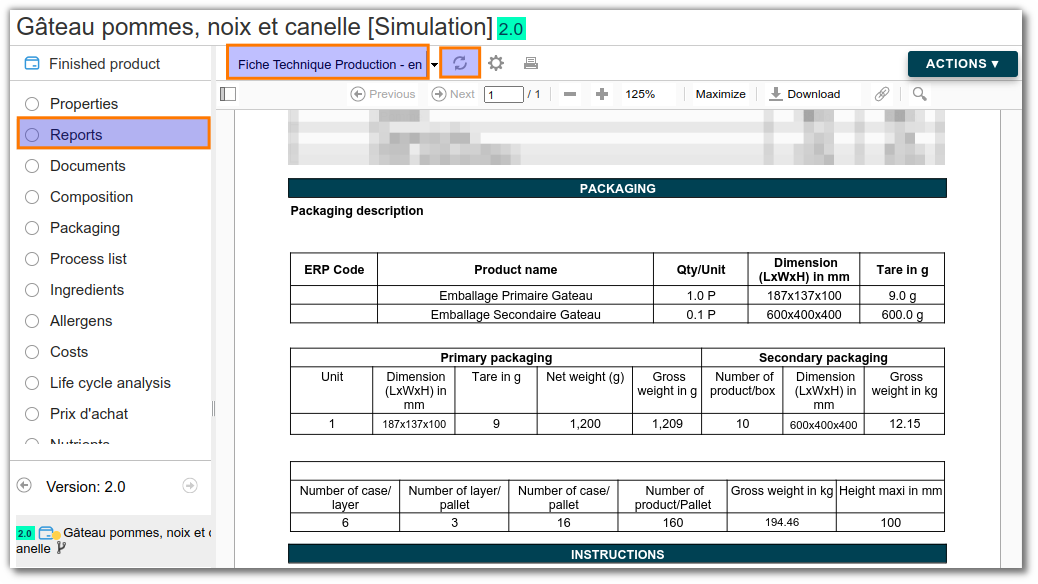

Technical data sheet

Go to the "Report" list and click on "Generate reports" to obtain the production data sheet on which the packaging description will appear:

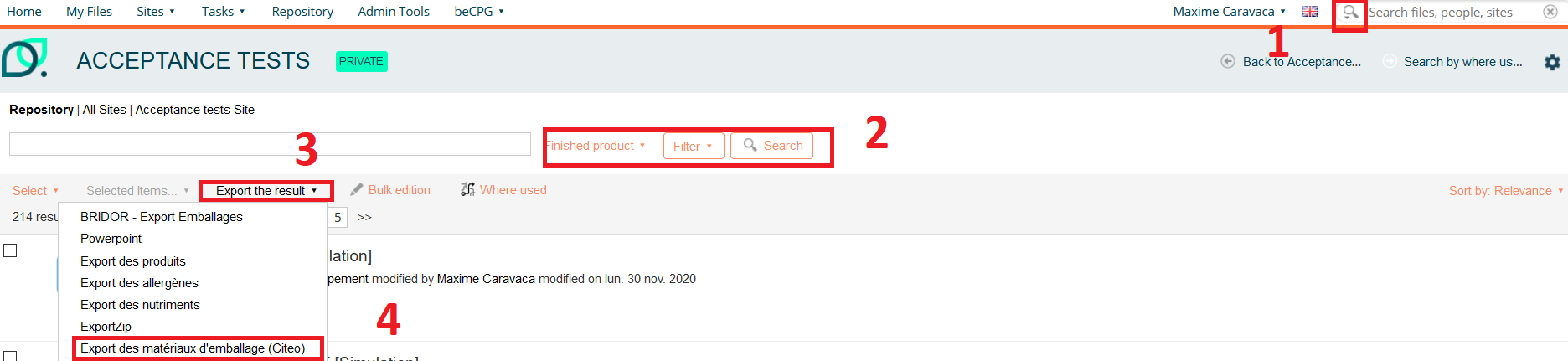

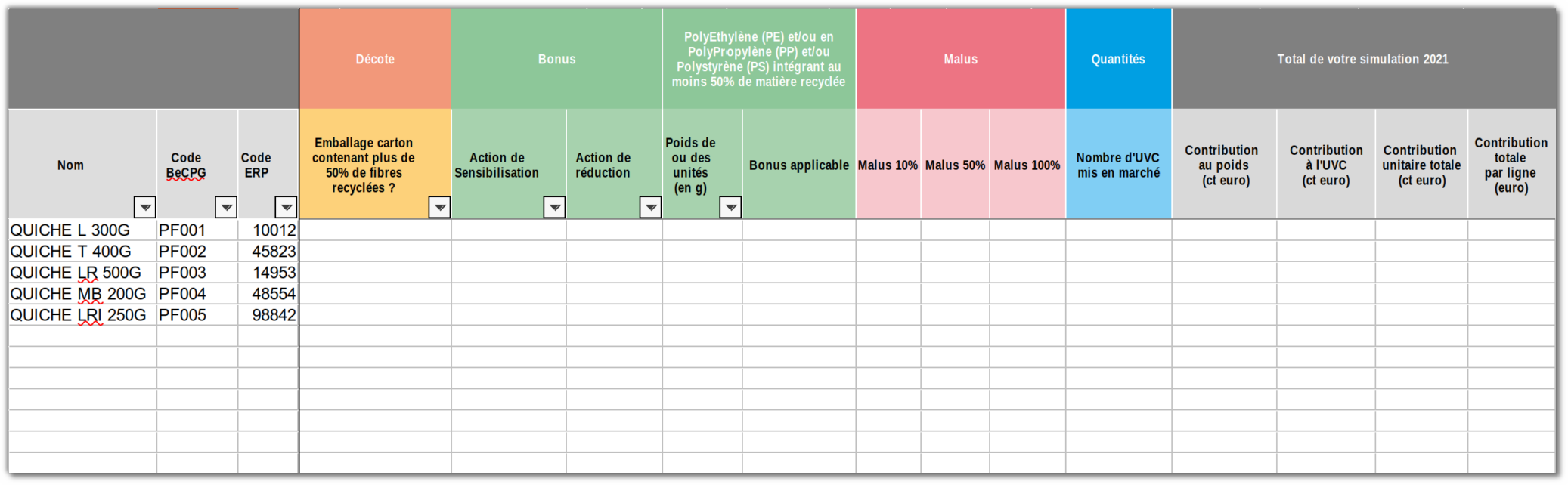

CITEO Report generation

CITEO Report is an export report, available in french, which can be generated out of an advanced search on finished products.

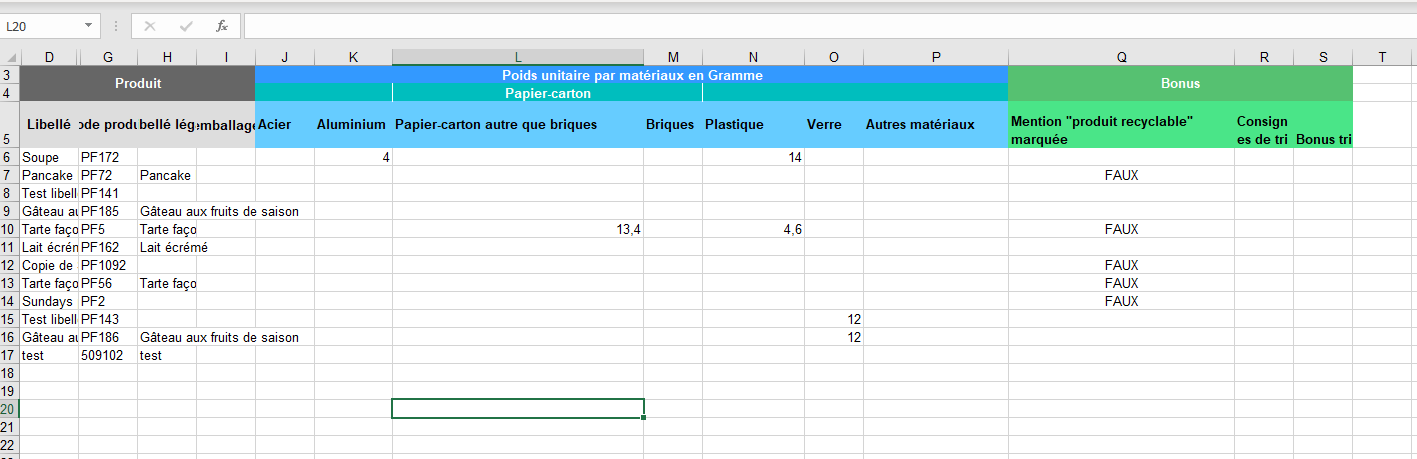

Once generated, we have an Excel document:

Materials are group by CITEO regulatory category. It's possible to add additional materials to be more precise than CITEO, provided that you fill in the CITEO category for the CITEO report to work.

For example: PET-1 --> 6.3.3 PET-2 --> 6.3.3