Process management

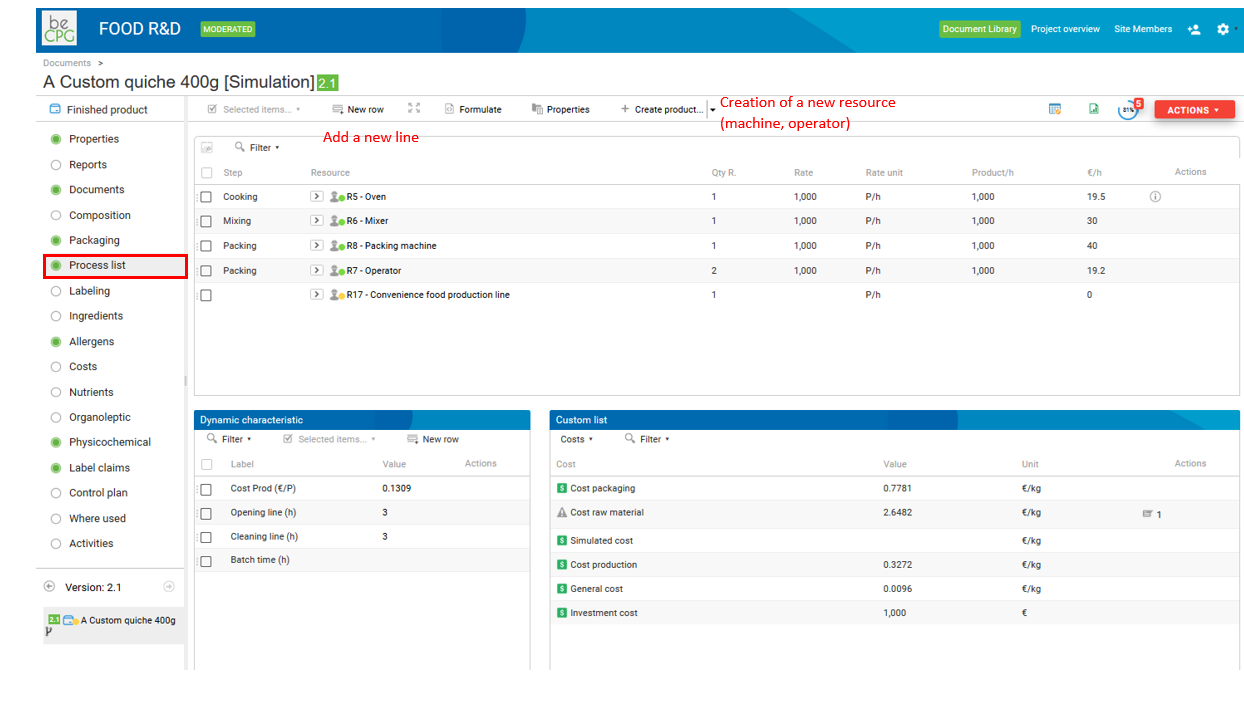

The process list allows you to enter production steps, lines, equipment and operators through resources.

For that, go first to Process List within an entity. Then, add a line per resource (e.g. Oven). If the resource doesn't exist, it is still possible to create a new resource with the "Create a product" menu.

Ressources

On your Finished Product, in the “Process list” list, add resources (e.g. Oven). If the resource does not exist, it is possible to create a new resource via the “Create a product” menu.

Resource parameters

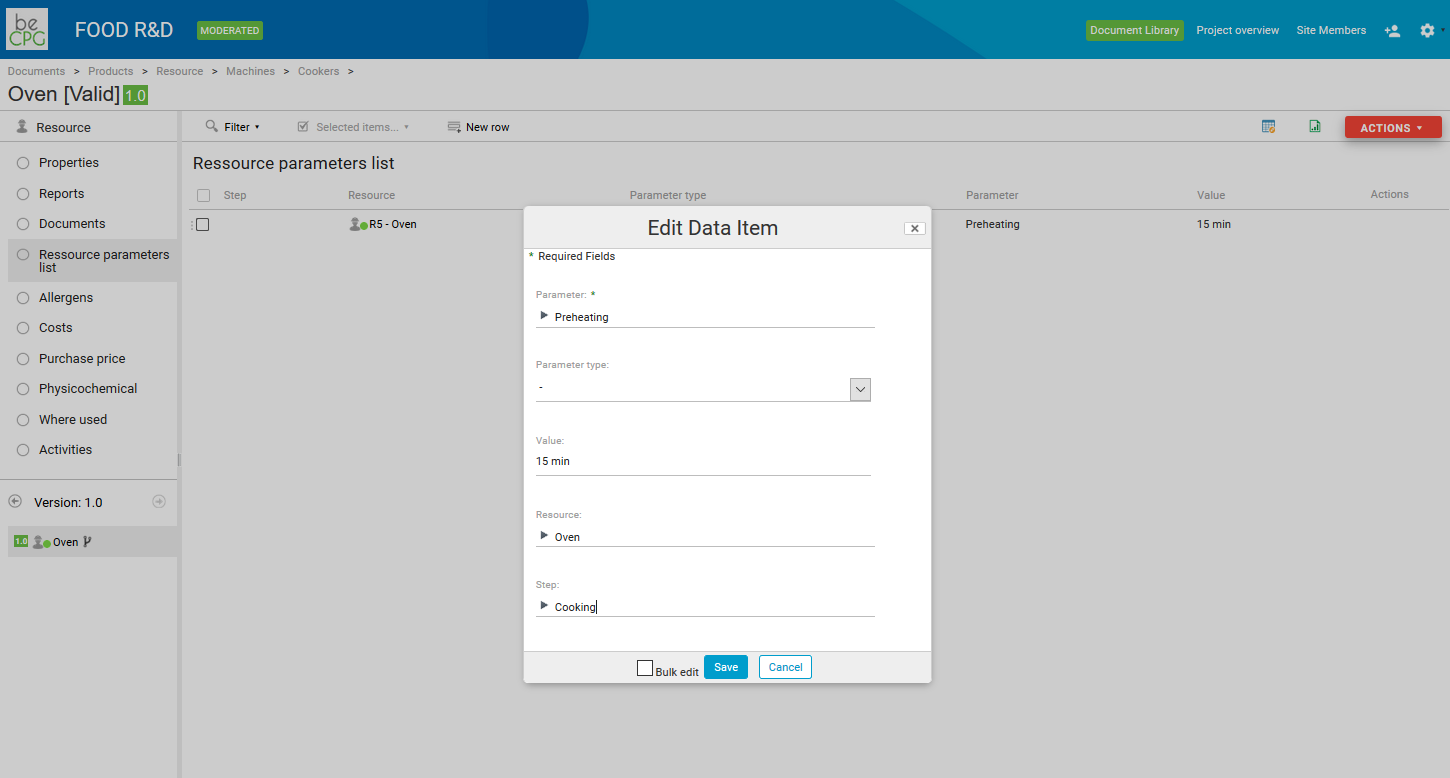

On Resources, it is possible to enter parameters (e.g. cooking time) in the Parameter list. These parameters appear in the “resource parameters” list of the finished product. The value of these parameters can be entered at different levels:

- On the finished product, if the value is product-specific

- On the resource, the value will be automatically entered at the time of creation, but will not be synchronized thereafter.

- On the finished product model, the value is synchronized with the model. It is therefore not possible to adjust it on a product-by-product basis.

Instruction

Instructions can be entered for each process line of the product. Parameters and instructions are included in the production sheet.

Ressource Cost

The cost of a resource is added in the resource cost tab. It is then reduced to a finished product according to the production rate of the finished product. For more information, go to the cost section. Click here

Process steps

Process steps and parameters are created in administration (Menu beCPG > Administration beCPG > Characteristics).