Process Order

The aim of process orders is to follow-up laboratory tests, sample production or industrial tests.

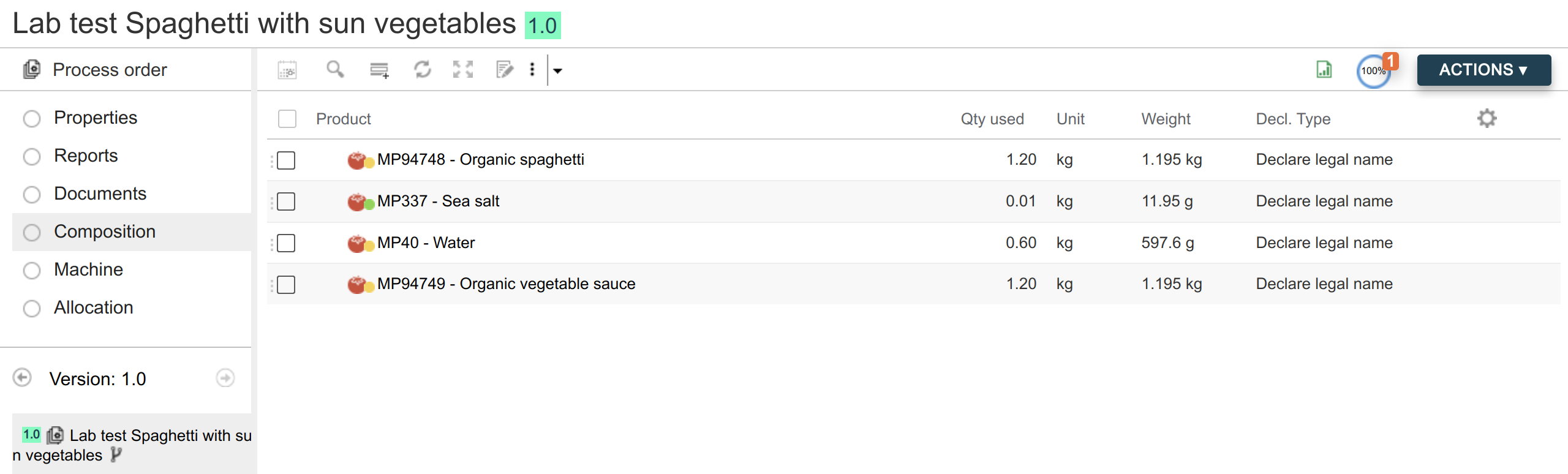

The process order allows you to:

- manage the laboratory stock;

- generate production sheets (where the composition of the product is rearranged in the production order);

- specify the quantity to be manufactured;

- follow the batches of materials used.

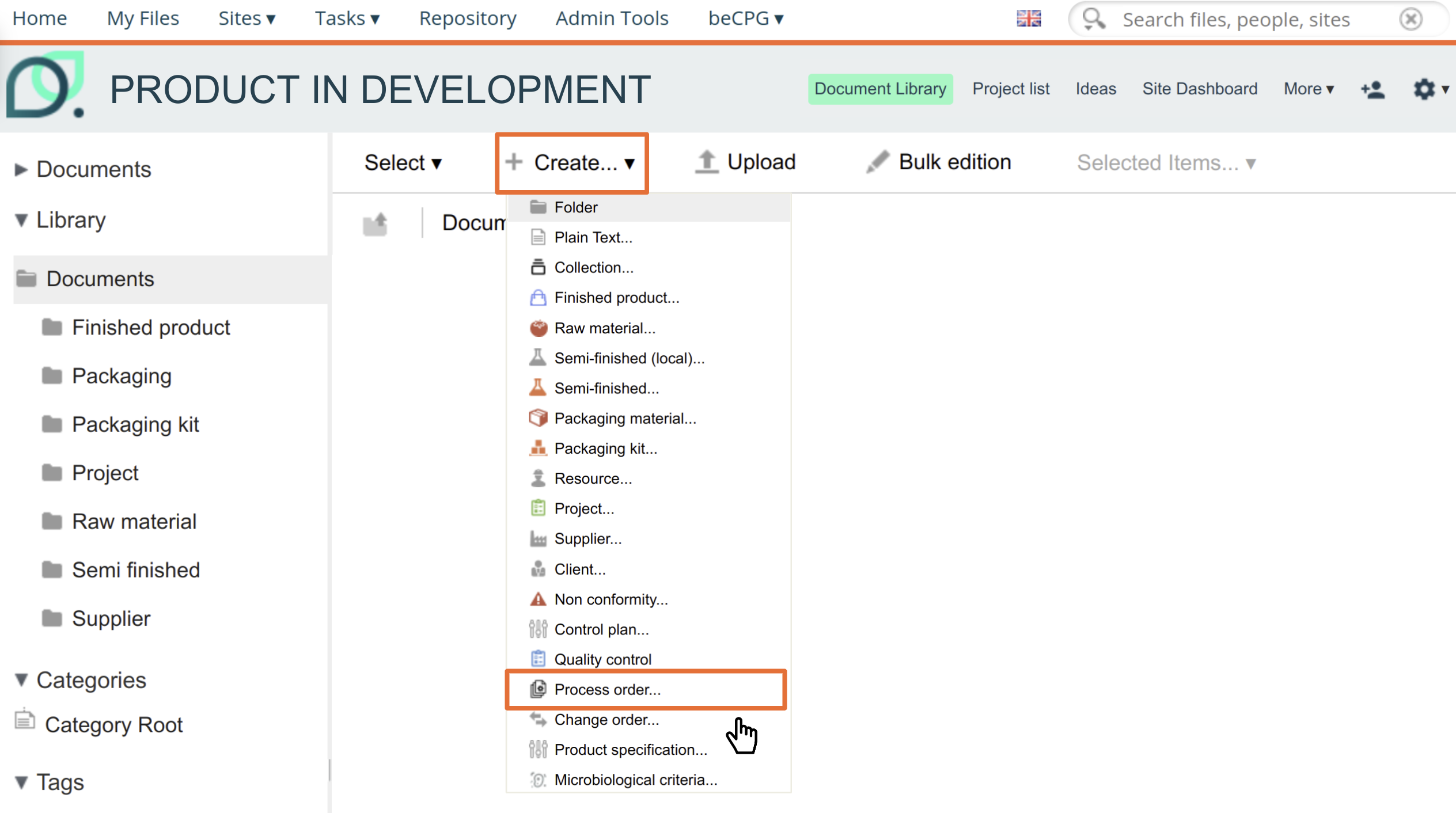

Create a process order

The process order is an entity available in the creation menu.

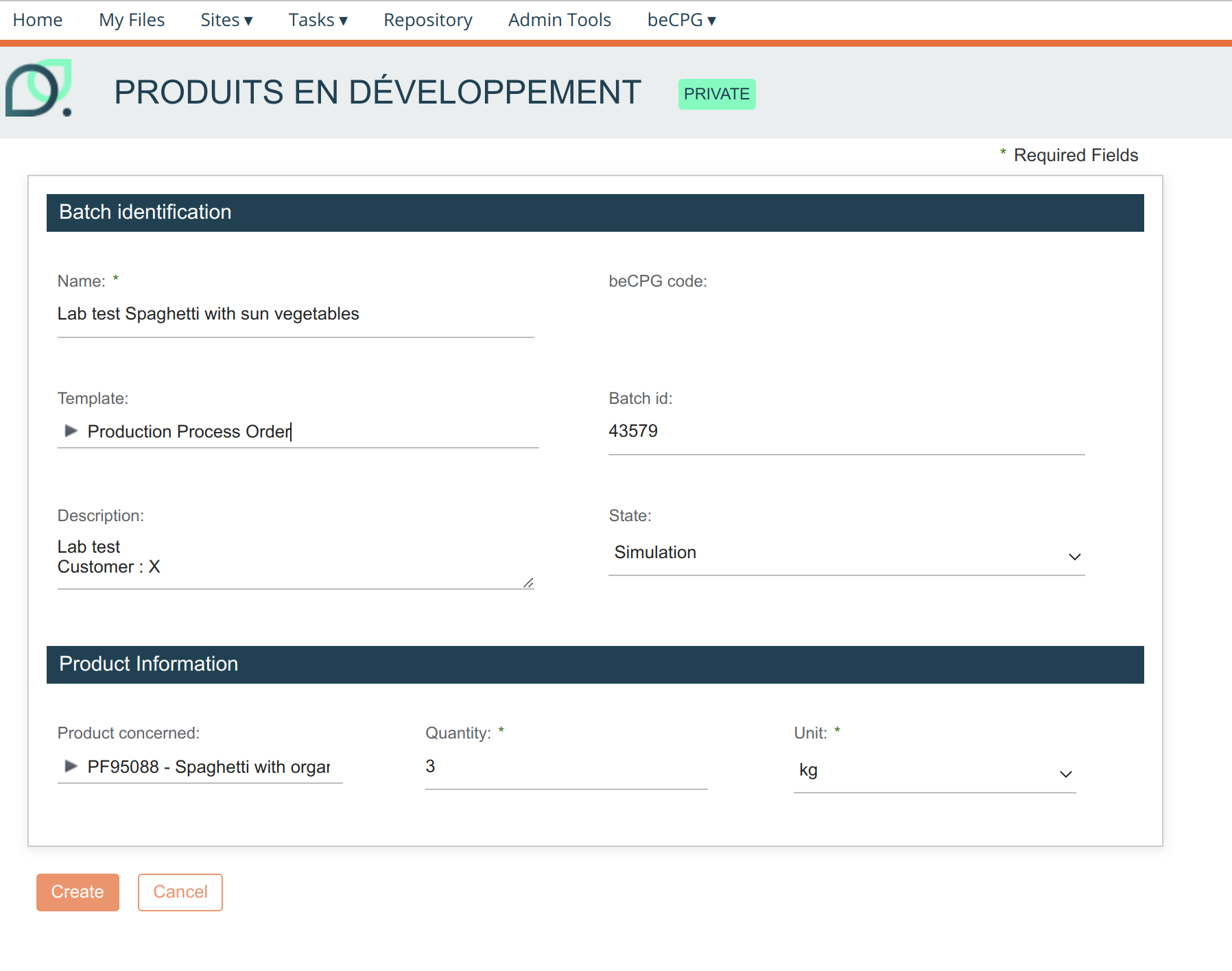

Complete the information of the change order (name, internal batch number....), then in the "product concerned" field, search for the finished product that will be affected by the production order.

Finally, indicate the quantity of the production (the composition of the product will be recalculated according to this quantity)

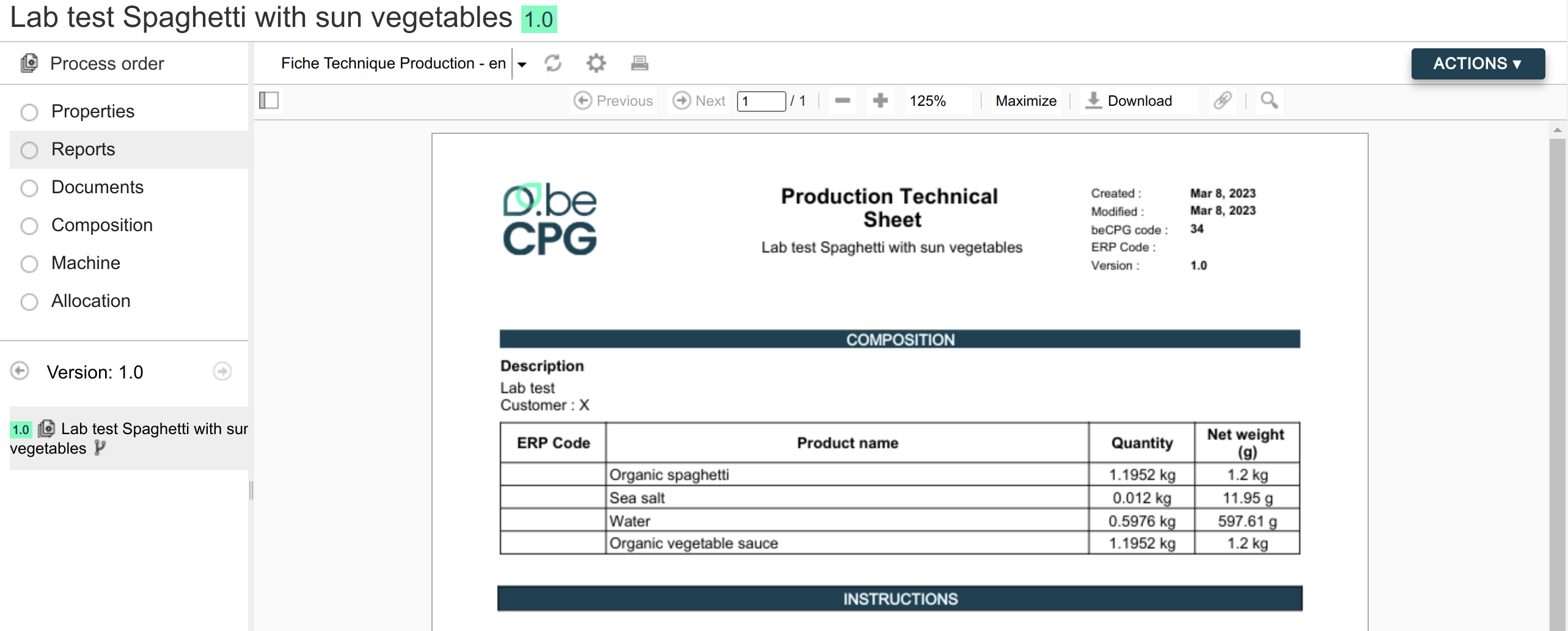

Report

In the report section, a production data sheet specific to the process order is available.

Stock management / Allocation

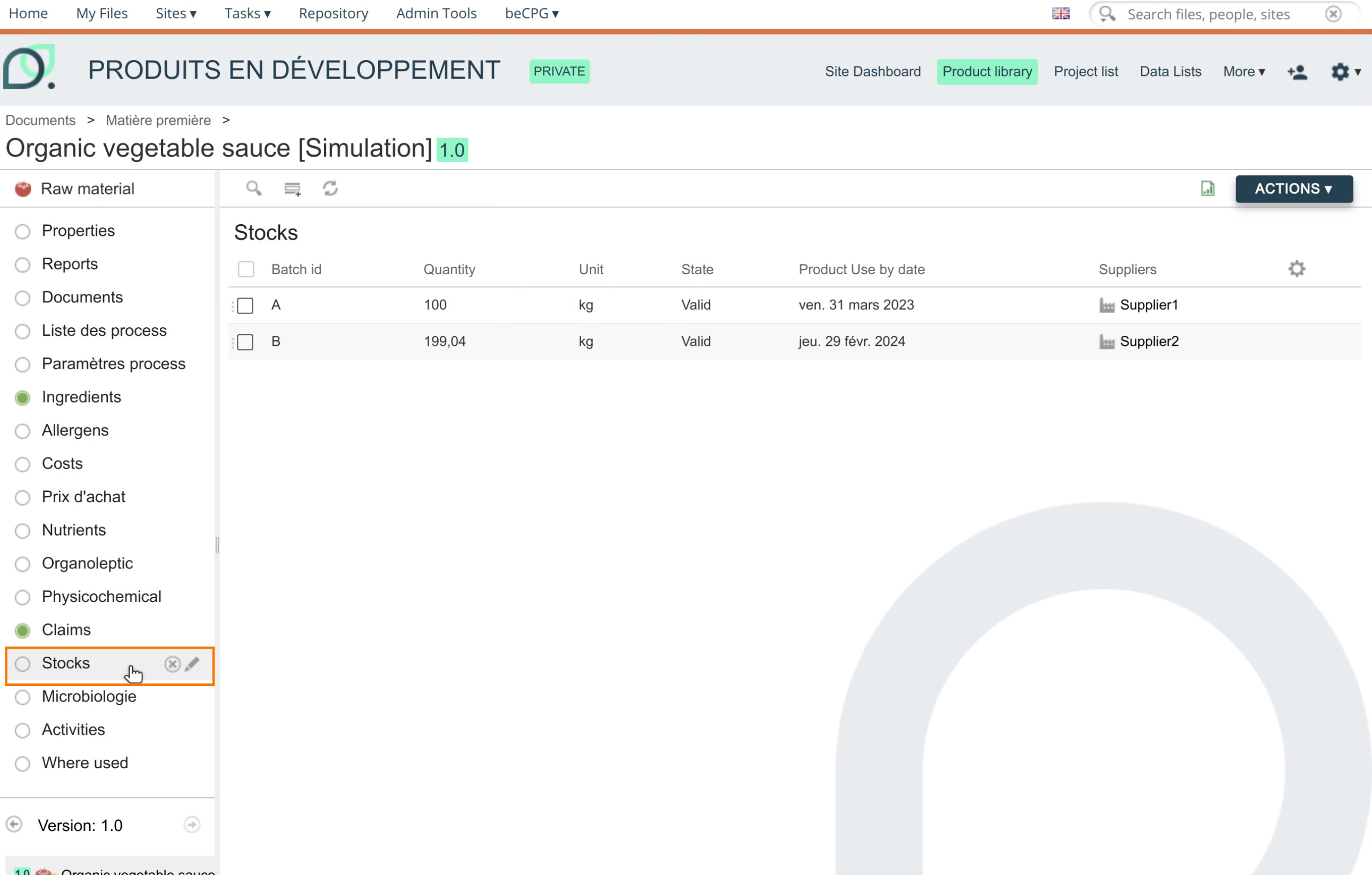

To do this, you must first complete the stocks of your RMs, in the Available Stock list. (If this list is not available, simply add it on your entity model)

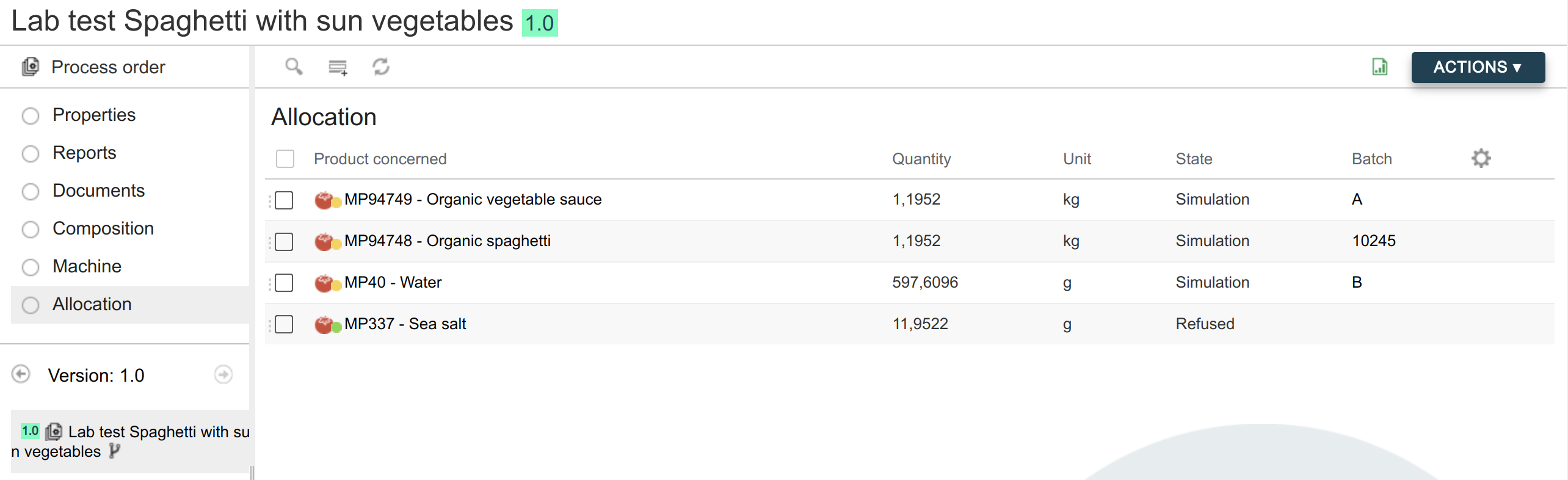

Then, in the allocation section on the process order, view the raw material requirement and availability. Different information is available:

- Quantity: recalculated according to the quantity of the test indicated in the properties

- State :

- Simulation: the stock is sufficient to carry out the process order

- Rejected: The stock is not sufficient to carry out the process order

- Batch: by editing the line, it is possible to choose the batch used

When the process order is executed (State = Validated), the stock of each material is updated according to the quantity consumed.

If a material is in the rejected state then the stock count will not be done